CL | Control Line Tubing Straighteners for Oil & Gas Applications

High-Precision Wire and Tube Straightening for Offshore and Land-Based Operations

Product Overview

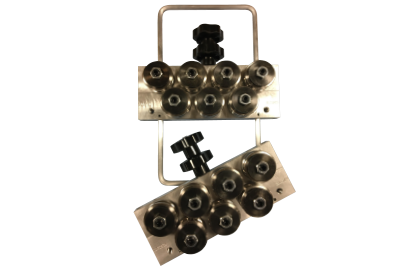

Sjogren’s Control Line Tubing Straighteners are engineered for offshore and land-based oil and gas applications. They provide precision alignment and tension control for slicklines, wirelines, and measuring lines, reducing downtime and improving operational efficiency.

With a lightweight and ergonomic design, these straighteners are easy to handle, even with gloves. The precision-engineered rollers help keep your lines straight, supporting wellbore operations with reliability and accuracy, regardless of the conditions.

Key Benefits

learn more about the control line straightener with our interactive model! You can dive right into technical specifications and model numbers here or scroll down the page!

1Ergonomic Handheld Design

Lightweight aluminum body for operator comfort and better control.

2Customizable Configurations

Offered with configurations of 5 or 7 rolls per plane, these models cater to diverse wire tension requirements, with sizes spanning from .250 inches to .750 inches.

3High Tensile Strength Rollers

Our Control Line series features custom rolls available in standard stainless steel or they can be modified to use alternative non-metal materials, designed to meet your precise specifications and endure high-stress conditions.

4Compact Size for Tight Spaces

Designed for easy handling by any operator! Our control line series straighteners are engineered to fit into confined operating areas without compromising performance and are generally light enough to be manually managed as you guide cables down while maintaining consistent slack tension.

5Consistent Wire Tension

Precision alignment minimizes wire breakage and maintains accurate measuring.

Why Choose Sjogren's Control Line Straighteners?

Sjogren’s Control Line Tubing Straightener is trusted by the largest oil and gas leaders around the globe because it delivers precise wire alignment in high-stress environments, every time it is put into action. Its ergonomic design reduces operator fatigue and its precision-machined rollers ensure consistent performance.

-

1. Built for Oil & Gas

-

Handles high-stress offshore and land-based environments.

-

2. Adaptable for Varying Wire Sizes

Stainless steel and our other trusted construction materials withstand harsh environmental conditions.

-

3. Operator Comfort

- Lightweight design minimizes strain during extended use.

-

4. Flexible Configurations

5 or 7 roll configurations for different wire tension needs in multiple sizes.

Industries & Applications

The Control Line Tubing Straightener is trusted by major players in:

Oil & Gas

Energy & Power

Industrial Manufacturing

Effective in demanding production environments.

Product Measurements and Technical Specifications

Control Line Series Breakdown by tube size models

View CL 250 Models

| P/N | Model | Extended Description | Roll Diameter D | Tube Size | Number of Rolls Per Plane | Length | Weight |

|---|---|---|---|---|---|---|---|

| 206645-03 | IS-507JR-1P U-GR-.250” DIA. |

Designed with a steel base, no handles and 5 steel rolls per plane for .250” tubing |

32 mm |

6,35 mm (.250") |

5 | 114,3 mm (4.5") |

1,82 kg (4 lbs.) |

| 206645-05 | IS-507JR-1P-S U-GR-.250” DIA. |

Designed with a steel base with handles and 5 steel rolls per plane for .250” tubing |

32 mm |

6,35 mm (.250") |

5 | 133,4 mm (5.25") |

2,73 kg (6 lbs.) |

| 338503-03 | NL-507-1PR U-GR-.250”DIA. |

Designed with a steel base, no handles and 5 steel rolls per plane for .250” tubing |

32 mm |

6,35 mm (.250") |

5 | 142,75 mm (5.62") |

2,73 kg (6 lbs.) |

| 886187-02 | NL-245-1PR U-GR-.250” DIA. |

Designed with a steel base, no handles and 5 steel rolls per plane for .250” tubing |

47 mm |

6,35 mm (.250") |

5 | 235,7 mm (9.28") |

7,27 kg (16 lbs.) |

| 448578-01 | CL-250-5-1P-S U-GR-.250” DIA. |

Designed with an aluminum base with handles and 5 stainless steel rolls per plane for .250” tubing | 52 mm (2.05") |

6,35 mm (.250”) | 5 | 260,1 mm (10.24") |

3,6 kg (8 lbs.) |

| 886580-01 | CL-52-7-1P U-GR-.250” DIA. |

Designed with an aluminum base with handles and 7 stainless steel rolls per plane for .250” tubing | 52 mm (2.05") |

6,35 mm (.250”) | 7 | 260,1 mm (10.24") |

4,55 kg (10 lbs.) |

View CL 375 Models

| P/N | Model | Extended Description | Roll Diameter D | Tube Size | Number of Rolls Per Plane | Length | Weight |

|---|---|---|---|---|---|---|---|

| 448578-02 | CL-375-5-1P-S U-GR-.375” DIA. |

Designed with an aluminum base with handles and 5 stainless steel rolls per plane for .375” tubing | 52 mm (2.05") |

9,35 mm (.375”) | 5 | 260,1 mm (10.24") |

3,6 kg (8 lbs.) |

| 448356-00 | CL-52-7-1P U-GR-.375” DIA. |

Designed with an aluminum base with handles and 7 stainless steel rolls per plane for .375” tubing | 52 mm (2.05") |

9,35 mm (.375”) | 7 | 260,1 mm (10.24") |

4,55 kg (10 lbs.) |

View CL 500 Models

| P/N | Model | Extended Description | Roll Diameter D | Tube Size | Number of Rolls Per Plane | Length | Weight |

|---|---|---|---|---|---|---|---|

| 448578-03 | CL-500-5-1P-S U-GR-.500” DIA. |

Designed with an aluminum base with handles and 5 stainless steel rolls per plane for .500” tubing | 80 mm (3.15") |

12,7 mm (.500”) | 5 | 457,2 mm (18.00") |

10,4 kg (23 lbs.) |

| 448578-08 | CL-500-7-1P-S U-GR-.500” DIA. |

Designed with an aluminum base with handles and 7 stainless steel rolls per plane for .500” tubing | 80 mm (3.15") |

12,7 mm (.500”) | 7 | 457,2 mm (18.00") |

12,7 kg (28 lbs.) |

View CL 625 Models

| P/N | Model | Extended Description | Roll Diameter D | Tube Size | Number of Rolls Per Plane | Length | Weight |

|---|---|---|---|---|---|---|---|

| 448578-04 | CL-625-5-1P-S U-GR-.625” DIA. |

Designed with an aluminum base with handles and 5 stainless steel rolls per plane for .625” tubing | 80 mm (3.15") |

15,87 mm (.625”) | 5 | 457,2 mm (18.00") |

10,4 kg (23 lbs.) |

| 448578-09 | CL-625-7-1P-S U-GR-.625” DIA. |

Designed with an aluminum base with handles and 7 stainless steel rolls per plane for .625” tubing | 80 mm (3.15") |

15,87 mm (.625”) | 7 | 457,2 mm (18.00") |

12,7 kg (28 lbs.) |

View CL 750 Models

| P/N | Model | Extended Description | Roll Diameter D | Tube Size | Number of Rolls Per Plane | Length | Weight |

|---|---|---|---|---|---|---|---|

| 448578-05 | CL-750-5-1P-S U-GR-.750” DIA. |

Designed with an aluminum base with handles and 5 stainless steel rolls per plane for .750” tubing |

80 mm |

19,05 mm (.750”) | 5 | 457,2 mm (18.00") |

10,4 kg (23 lbs.) |

| 448578-10 | CL-750-7-1P-S U-GR-.750” DIA. |

Designed with an aluminum base with handles and 7 stainless steel rolls per plane for .750” tubing | 80 mm (3.15") |

19,05 mm (.750”) |

7 | 457,2 mm (18.00") |

12,7 kg (28 lbs.) |

Download the Application Data Sheet

Complete the Application Data Sheet to engage our expert engineering team today and implement Sjogren quality Control Line Straighteners into your production!

See some of our satisfied customers

Control Line Tubing Straightener FAQ

How does the ergonomic design help operators?

These control line straighteners are lightweight (as lightweight as we can make them without compromising quality!) and well-balanced, making them easier to use for long periods without strain.

How do I order replacement rolls to stay ahead of downtime?

Breakdown on rolls is heavily dependent on your use and environment. We make our rolls to withstand tough conditions out on the water or on land.

Contact us with your model number and wire specs for custom options. You can use the contact form at the bottom of this page or you can email our team directly at sales@sjogren.com.

Can these control line models handle tough offshore conditions?

Yes — the aluminum and other model body materials and stainless steel rollers and even our rollers made of other materials are made to resist corrosion from saltwater and harsh environments.

What’s the difference between 5-roll and 7-roll models?

Our 7-roll models offer better precision, while 5-roll models allow quicker adjustments.

What do these models cost?

Our products are made of the highest quality materials, with precision engineering. They may cost more than your average straightener from competitors, but they last longer.

We do offer volume pricing on almost all of our products, so take this into consideration when requesting quotation!

It costs our manufacturing line less to produce 5 or more of a product than it does to produce 1 in one run, and we share these savings with you.

Do you have a control line straightener catalog available?

We do! It is easily accessible for download in our main menu, and also here!

Get Your Custom CL straightener Quote – Fast & Reliable Pricing and Delivery!

Tell us your wire processing needs, and our team will provide a tailored quote quickly. Get the best solution for precision wire straightening today!