Heavy Duty Wire Pullers

Product Overview

Engineered specifically for high-intensity, high-pull force applications, like die-pulling, the Heavy Duty Wire Puller models offer rugged durability to significantly enhance productivity and minimize downtime.

Trusted across demanding sectors and well-known companies around the globe, these puller and puller assemblies ensure peak performance, reliability, and ease of maintenance in rigorous industrial environments.

Compatible with Morgan-style wire puller-block assemblies, Sjogren’s pullers deliver operational flexibility and simplified maintenance for procurement, engineering, and production teams.

You will find an interactive model highlighting key benefits, as well as key benefits and who benefits most from these on this page. We also have compiled recommended assemblies, replacement parts and accessories, and answer common questions about the M-Series puller.

Only available from Sjogren and our affiliates noted on our rep locator page!

Key Benefits

learn more about the heavy duty puller from Sjogren with our interactive model or dive into technical specifications further down the page.

1 Robust Construction

2 Highly Compatible

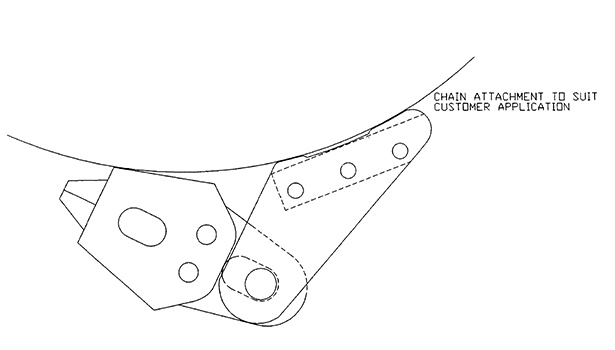

3 Tangential Die-Pulling Option (Clevis)

4 High Load Capacity

5 Easy Jaw Replacement

Why Choose Sjogren's Heavy-Duty Morgan-Style Wire Pullers?

1. Maximized Jaw Life

2. Reduced Operational Downtime

3. Prevent Wire Breakage Under High Stress

4. Easy Integration into Existing Operations

Industries and Applications

The Heavy-Duty Puller line from Sjogren is optimized for performance-critical industries including but not at all limited to:

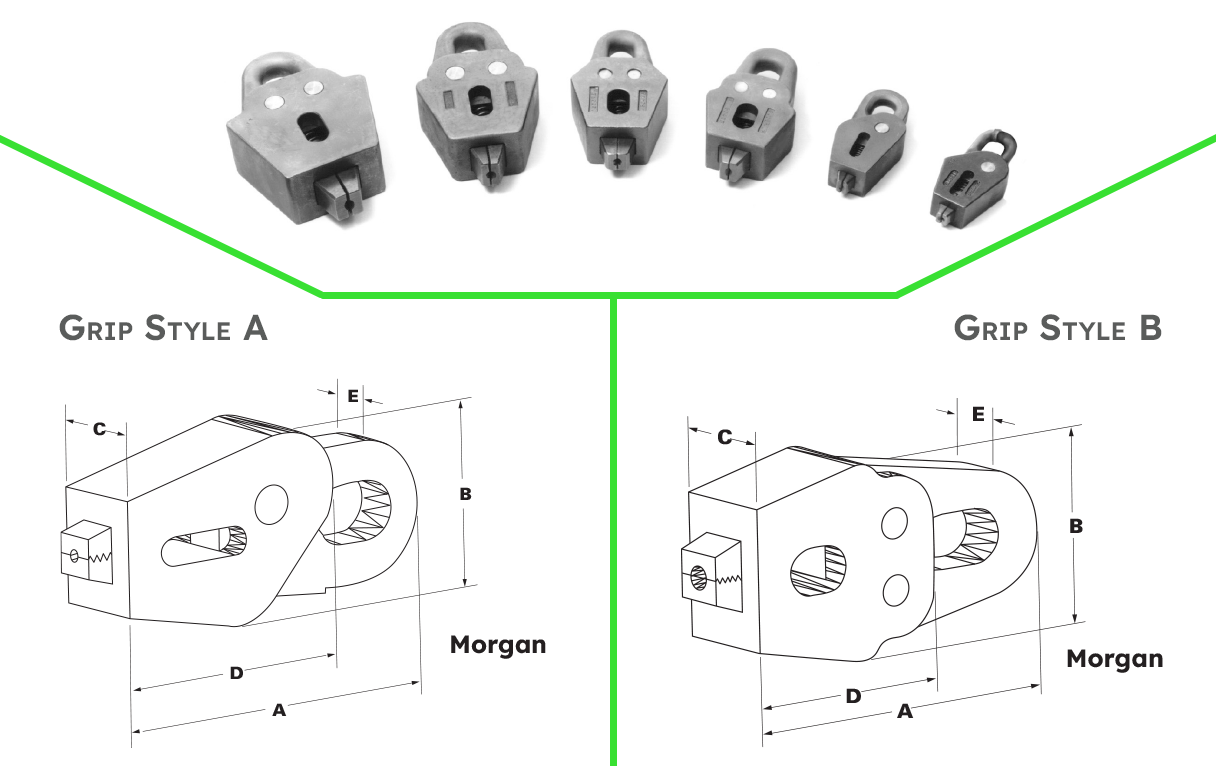

M-Series Wedge Grip Wire Puller Measurements and Technical Specifications

Discover detailed specifications and recommended accessories below in our user-friendly, collapsible technical tables.

M-Series Wedge Grip Specifications

View Heavy-Duty M-Series Puller Models and Tech Specs

Grip Style Part No.* Grip Head Model Max. Pointed Size Min. Wire Size Max Pull (lbs.) (kg) Sketch Dimensions (Inches) Weight (lbs.) (kg) A B C D E A 306033-02 B-20072 .125″

3,2 mm— 1,500 lbs.

681,8 kg6.50″

165,10 mm2.19″

55,56 mm1.13″

28,58 mm3.00″

76,20 mm0.44″

11,11 mm1.5 lbs.

0,7 kg306036-02 B-30251 .25″

6,4 mm.062″

1.6 mm2,500 lbs.

1136,4 kg4.75″

120,65 mm2.25″

57,15 mm1.25″

31,75 mm3.13″

79,38 mm0.56″

14,29 mm2 lbs.

0,9 kgB 306039-02 B-30423 .375″

9,5 mm.187″

4,8 mm8,000 lbs.

3636,4 kg5.63″

142,88 mm3.25″

82,55 mm1.75″

44,45 mm3.38″

85,73 mm0.88″

22,23 mm4.5 lbs.

2,0 kg306046-02 B-74900 .5″

12,7 mm.312″

7,9 mm15,000 lbs.

6818,2 kg6.63″

168,28 mm4.38″

111,13 mm2.13″

53,98 mm2.13″

53,98 mm1.06″

26,99 mm9 lbs.

4,1 kg406029-01 B-74958 .625″

15,9 mm.437″

11,1 mm20,000 lbs.

9090,9 kg7.00″

177,80 mm5.25″

133,35 mm2.38″

60,33 mm4.75″

120,65 mm1.00″

25,40 mm12.5 lbs.

5,7 kg306057-02 B-74934 1.0″

25,4 mm.562″

14,3 mm40,000 lbs.

18181,8 kg9.50″

241,30 mm6.63″

168,28 mm3.50″

88,90 mm6.13″

155,58 mm1.25″

31,75 mm30.5 lbs.

13,9 kg

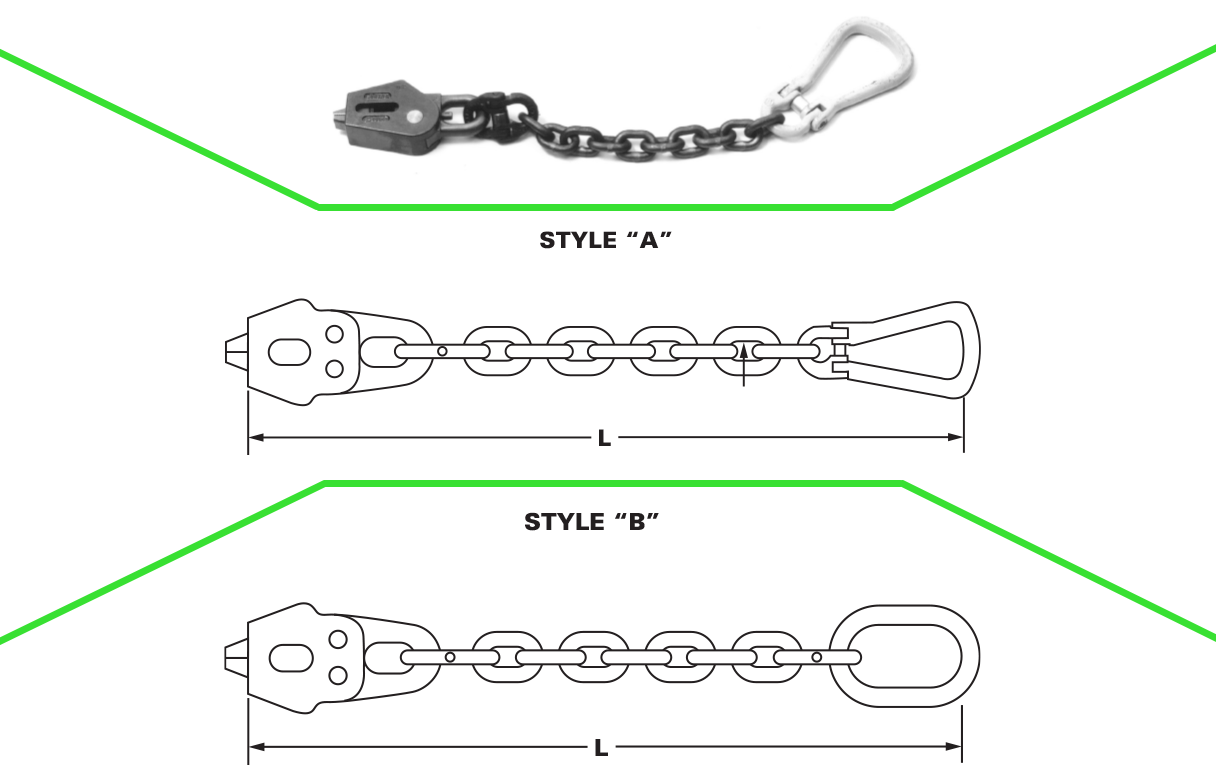

Morgan Heavy-Duty (M-Series) Wire Grip Standard Assemblies

View M-Series Standard Recommended Assembly Options

Assembly

NumberGrip Head Number Max.

Pointed

SizeMin.

Wire

SizeMax.

Pull

(lbs./kg)Assembly

StyleChain Size Hook

StyleHook

SizeStandard

Length

“L”Weight (lbs./kg) 306033-01 B-20072 .125″

3,2 mmN/A 1,500 lbs.

681,8 kgA 0.25″

6,35 mmReevable 0.25″

6,35 mm19.25″

488,95 mm3.25 lbs.

1,5 kg306036-01 B-30251 .25″

6,4 mm.062″

1,6 mm2,500 lbs.

1136,4 kgA 0.38″

9,53 mmReevable 0.38″

9,53 mm22.50″

571,50 mm6 lbs.

2,7 kg306039-01 B-30423 .375″

9,5 mm.187″

4,8 mm8,000 lbs.

3636,4 kgA 0.50″

12,70 mmReevable 0.50″

12,70 mm28.00″

711,20 mm10.75 lbs.

4,88 kg306046-01 B-74900 .5″

12,7 mm.312″

7,9 mm15,000 lbs.

6818,2 kgA 0.63″

15,88 mmReevable 0.63″

15,88 mm30.25″

768,35 mm19 lbs.

8,62 kg406029-02 B-74958 .625″

15,9 mm.437″

11,1 mm20,000 lbs.

9090,9 kgA 0.75″

19,05 mmReevable 0.75″

19,05 mm35.00″

889,00 mm29 lbs.

13,15 kg306057-01 B-74934 1.0″

25,4 mm.562″

14,3 mm40,000 lbs.

18181,8 kgB 1.00″

25,40 mmOblong 1.00″

25,40 mm36.50″

927,10 mm57.5 lbs.

25,85 kg

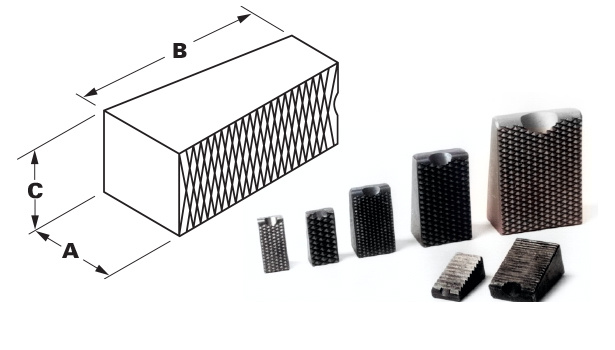

Replacement Parts for M-Series Wire Puller Models

Replacement Jaws

View Replacement JAWS for V-Series Wedge Grip Models

Part Number Jaw Model Sketch Dimensions

Teeth Per Inch (TPI) Standard Custom Patterns* A B C Diamond Diamond Straight 106626-01 B-20072 0.53″

13,49 mm1.13″

28,58 mm0.50″

12,70 mm16 25 N/A 106626-02 B-30251 0.53″

13,49 mm1.13″

28,58 mm0.56″

14,29 mm16 N/A 10, 16 106626-07 B-30423 0.81″

20,64 mm1.38″

34,93 mm0.88″

22,23 mm16 0.31″

7,94 mm16 106626-03 B-30425 0.81″

20,64 mm1.38″

34,93 mm0.81″

20,64 mm16 0.53″

13,49 mm10 106626-04 B-74900 0.94″

23,81 mm1.75″

44,45 mm1.13″

28,58 mm10 N/A 10, 16 106626-05 B-74958 1.13″

28,58 mm1.94″

49,21 mm1.13″

28,58 mm10 N/A 10, 16 106626-06 B-74934 1.38″

34,93 mm2.50″

63,50 mm1.88″

47,63 mm10 N/A 10

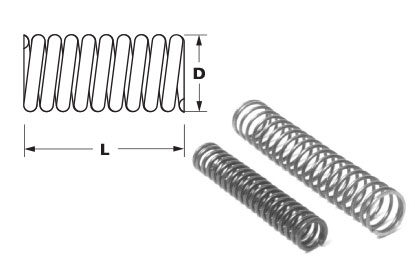

Springs

View Replacement Springs for M-Series Wedge Grip Models

*One spring required per grip head assemblyPart No. Fits Grip Head Outside Diameter “D” Free Length “L” Replaces Morgan No. 106103-01 B-20072 0.38″

9,53 mm1.56″

39,69 mm478-1 106103-02 B-30251 0.47″

11,91 mm2.00″

50,80 mm478-2 106103-47 B-30423 0.66″

16,67 mm2.25″

57,15 mm478-3 106103-47 B-30425 0.66″

16,67 mm2.25″

57,15 mm478-3 106103-04 B-74900 0.91″

23,02 mm2.50″

63,50 mm478-4 106103-04 B-74958 0.91″

23,02 mm2.50″

63,50 mm478-4 106103-05 B-74934 1.50″

38,10 mm4.38″

111,13 mm478-5

Accessories & Hooks for Morgan Wire Pulling Grips

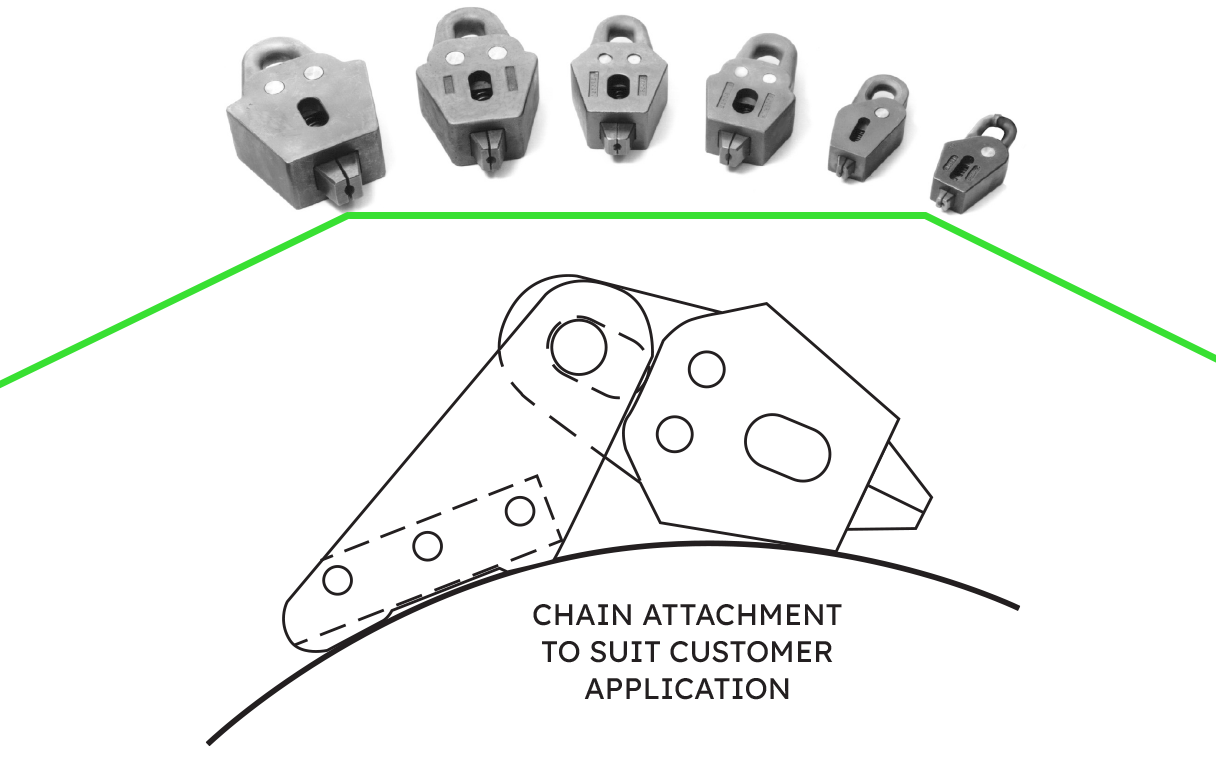

Additionally, we offer an extensive selection of hooks in various standard lengths, including reevable masters, hammerlock couplings, and oblong master hooks. These options ensure smooth integration into any production line, and we can also customize solutions beyond our standard offerings with different chain options including safety chain, link, and leaf chains, depending on your pull force and production requirements.

Explore more about your accessory and hook options below.

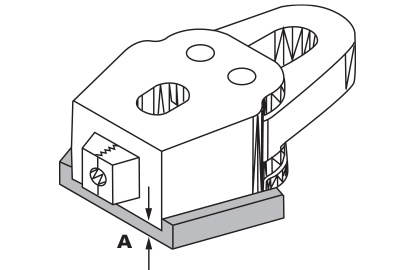

Accessories

View Aluminum Shoes for Morgan Style Grips

An optional aluminum shoe can help reduce marking on the capstan caused by slap during start-up.Part No. Fits Grip Head Thickness “A” 227434-00 B-20072 .187″

3,17 mm227435-00 B-30251 .187″

3,17 mm338294-00 B-30423 .25″

6,35 mm338296-00 B-74900 .25″

6,35 mm338094-00 B-74958 .25″

6,35 mm338297-00 B-74934 .25″

6,35 mm

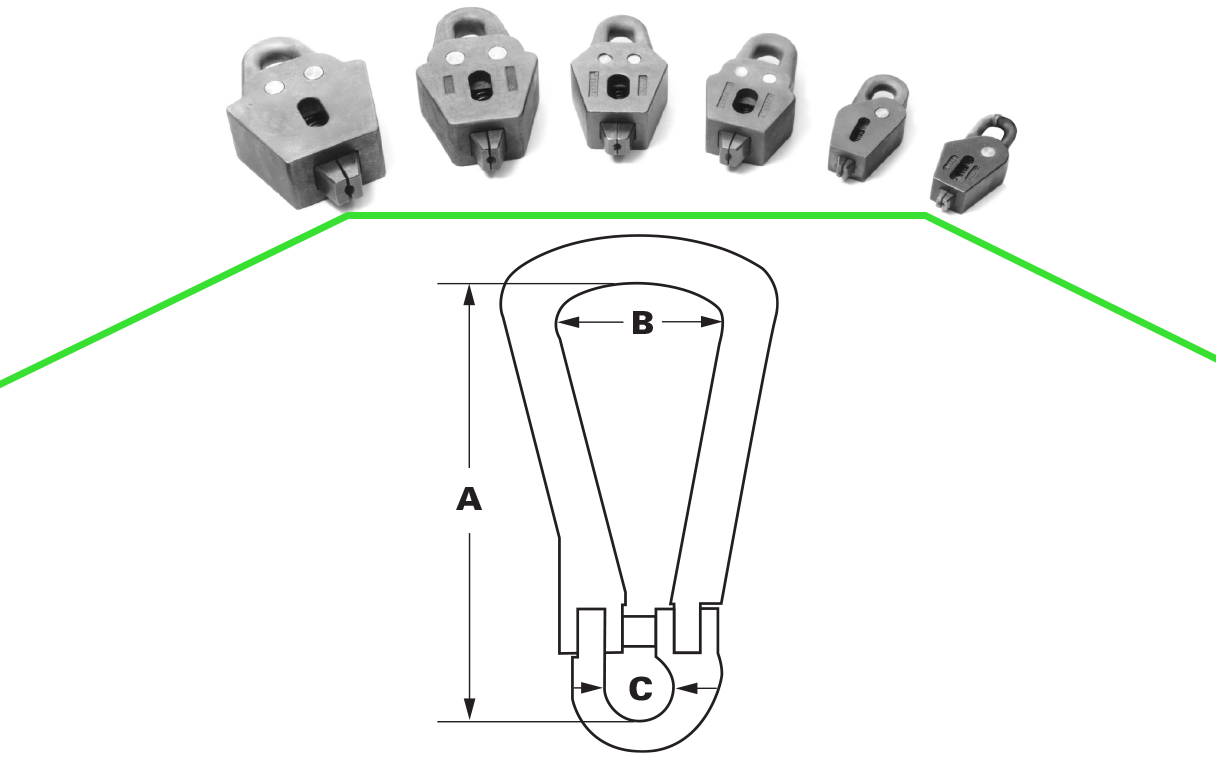

Hooks for Morgan (M-Series) Model Pullers

Hooks for Morgan (M-Series) Wire Pullers

View Reevable Master Hook Options

Part

NumberLink

SizeLength

“A”Width

“B”Width

“C”Max Pull

Rating

(lbs./kg)Weight

(lbs./kg)227222-01 0.25″

6,35 mm5.00″

127,00 mm2.00″

50,80 mm0.56″

14,29 mm3,000 lbs.

1360,8 kg.5 lbs.

0,2 kg227222-02 0.38″

9,53 mm6.38″

161,93 mm2.63″

66,68 mm0.75″

19,05 mm6,000 lbs.

2721,6 kg1.25 lbs.

0,6 kg227222-03 0.50″

12,70 mm7.38″

187,33 mm2.88″

73,03 mm0.94″

23,81 mm10,000 lbs.

4536,0 kg2 lbs.

0,9 kg227222-04 0.63″

15,88 mm9.00″

228,60 mm3.25″

82,55 mm1.25″

31,75 mm15,000 lbs.

6804,0 kg3.5 lbs.

1,6 kg227222-05 0.75″

19,05 mm10.38″

263,53 mm4.13″

104,78 mm1.38″

34,93 mm25,000 lbs.

11340,0 kg5.75 lbs.

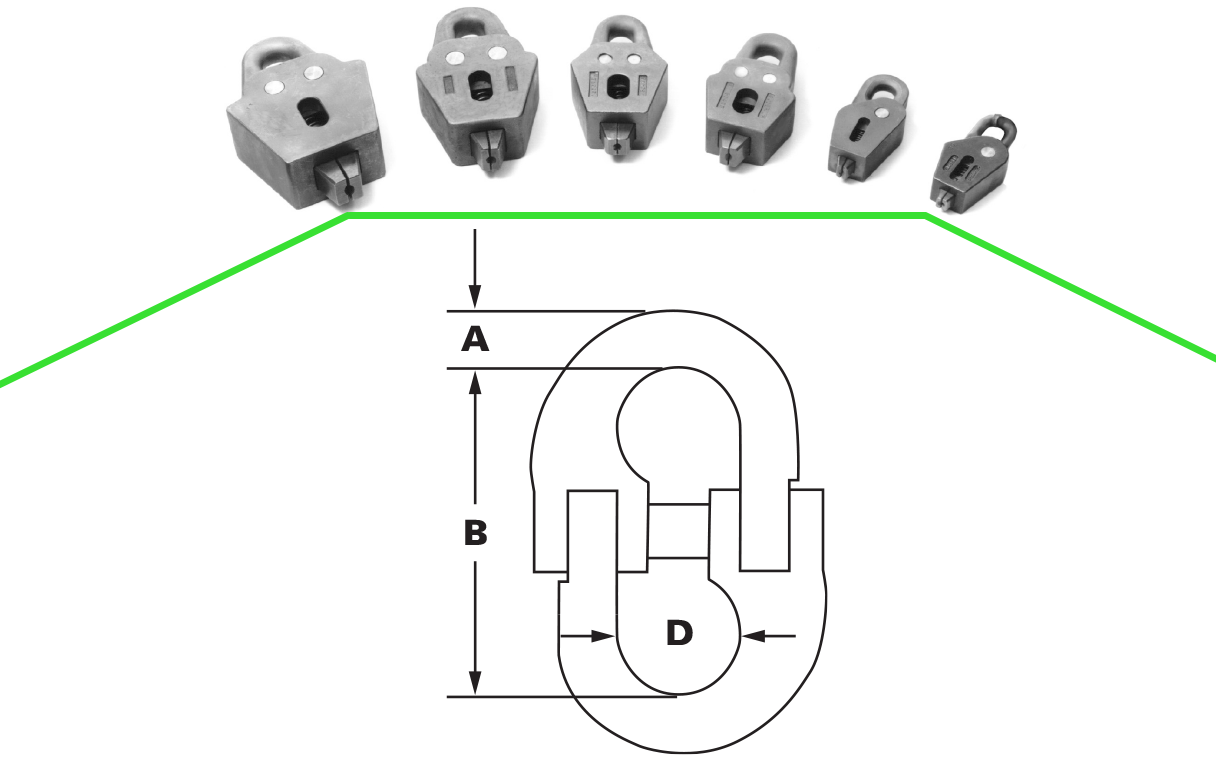

2,6 kgView Hammerlock Coupling Hook Options

Part

NumberLink

SizeDiameter

“A”Length

“B”Diameter

“D”Max Pull

Rating

(lbs./kg)Weight

(lbs./kg)227223-02 0.25″

6,35 mm0.31″

7,94 mm1.81″

46,04 mm0.50″

12,70 mm3,000 lbs.

1360,8 kg.25 lbs.

0,1 kg227223-03 0.38″

9,53 mm0.44″

11,11 mm2.81″

71,44 mm0.81″

20,64 mm6,000 lbs.

2721,6 kg.5 lbs.

0,2 kg227223-04 0.50″

12,70 mm0.63″

15,88 mm3.38″

85,73 mm1.25″

31,75 mm10,000 lbs.

4536,0 kg1.25 lbs.

0,6 kg227223-05 0.63″

15,88 mm0.75″

19,05 mm4.06″

103,19 mm1.50″

38,10 mm15,000 lbs.

6804,0 kg2.25 lbs.

1,0 kg227223-06 0.75″

19,05 mm0.88″

22,23 mm4.81″

122,24 mm1.81″

46,04 mm25,000 lbs.

11340,0 kg3.5 lbs.

1,6 kg227223-07 0.88″

22,23 mm1.00″

25,40 mm5.44″

138,11 mm2.13″

53,98 mm30,000 lbs.

13608,0 kg6 lbs.

2,7 kg227223-08 1.00″

25,40 mm1.25″

31,75 mm5.75″

146,05 mm2.19″

55,56 mm40,000 lbs.

18144,0 kg8.5 lbs.

3,9 kg227223-09 1.25″

31,75 mm1.50″

38,10 mmm7.19″

182,56 mm2.81″

71,44 mm60,000 lbs.

27216,0 kg15.5 lbs.

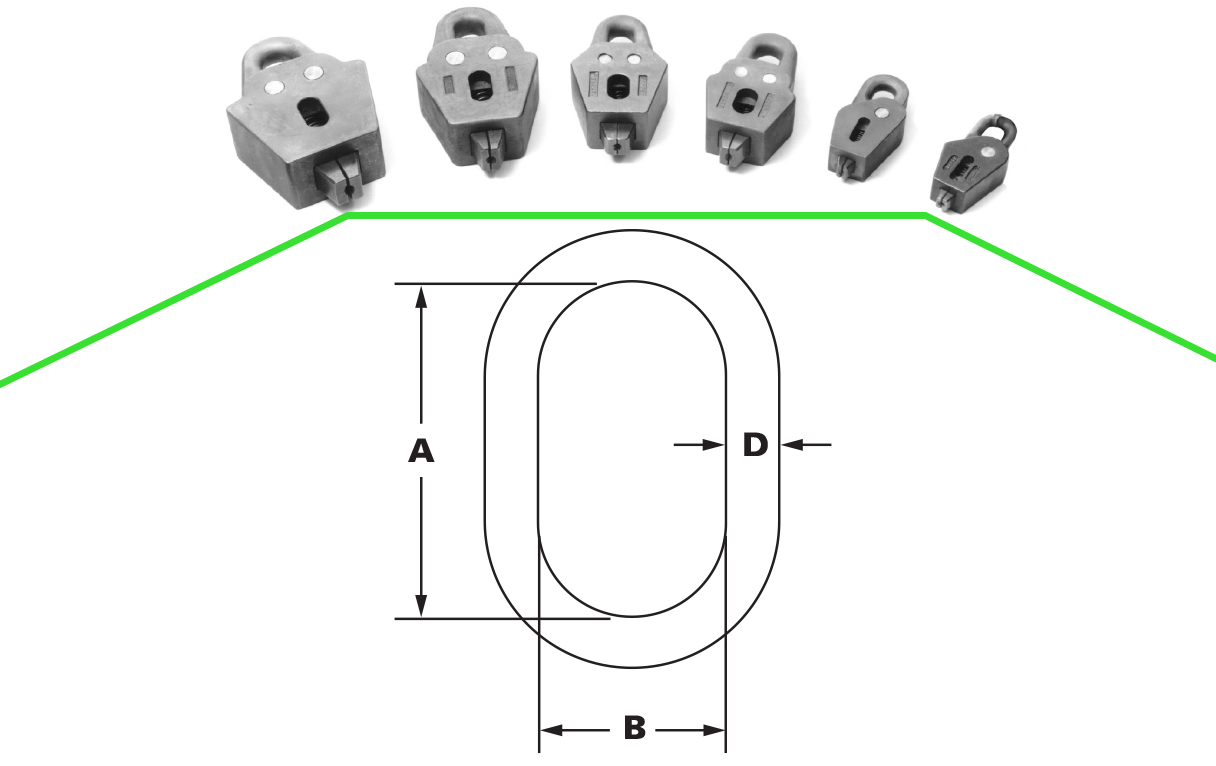

7,0 kgView Oblong Master Hook Options

Part

NumberLink

SizeDiameter

“A”Length

“B”Diameter

“D”Max Pull

Rating

(lbs./kg)Weight

(lbs./kg)119082-01 0.25″

6,35 mm1.50″

38,10 mm0.88″

22,23 mm0.38″

9,53 mm3,000 lbs.

1360,8 kg.25 lbs.

0,1 kg119082-02 0.38″

9,53 mm2.00″

50,80 mm1.25″

31,75 mm0.50″

12,70 mm6,000 lbs.

2721,6 kg5 lbs.

0,2 kg119082-03 0.50″

12,70 mm2.50″

63,50 mm1.50″

38,10 mm0.69″

17,46 mm10,000 lbs.

4536,0 kg1 lbs.

0,5 kg119082-04 0.63″

15,88 mm3.00″

76,20 mm1.75″

44,45 mm0.81″

20,64 mm15,000 lbs.

6804,0 kg1.5 lbs.

0,7 kg119082-05 0.75″

19,05 mm3.50″

88,90 mm2.00″

50,80 mm0.94″

23,81 mm25,000 lbs.

11340,0 kg2.5 lbs.

1,1 kg119082-06 0.88″

22,23 mm4.00″

101,60 mm2.25″

57,15 mm1.06″

26,99 mm30,000 lbs.

13608,0 kg3.25 lbs.

1,5 kg119082-07 1.00″

25,40 mm5.25″

133,35 mm3.00″

76,20 mm1.25″

31,75 mm40,000 lbs.

18144,0 kg6 lbs.

2,7 kg119082-08 1.25″

31,75 mm6.25″

158,75 mm3.50″

88,90 mm1.50″

38,10 mm60,000 lbs.

27216,0 kg9 lbs.

4,1 kg

Clevis-Type Assemblies

View Clevis Type Assembly Options

Part No. Replaces

Model NumberMax. Wire

SizeMin. Wire

SizeMax. Pull Rating

(lbs./kg)338310-00 B-20072-C .125″

3,17 mm— 1,500 lbs.

680,4 kg338311-00 B-30251-C .25″

6,35 mm.062″

1,57 mm2,500 lbs.

1136,4 kg306039-09 B-30423-C .357″

9,5 mm.187″

4,76 mm8,000 lbs.

3628,8 kg338313-00 B-74900-C .5″

12,7 mm.312″

7,9 mm15,000 lbs.

6804,0 kg447592-00 B-74958-C .625″

15,8 mm.437″

11,11 mm20,000 lbs.

9072,0 kg447593-00 B-74934-C 1.0″

25,4 mm.562″

14,2 mm40,000 lbs.

18144,0 kg

Download the Application Data Sheet

Complete the Application Data Sheet to engage our expert engineering team today and implement Sjogren quality straighteners into your production!

Want to See Other Puller Models?

Look into our other light duty models, or dive back into our main product page to find the right model for you!

Experience the Sjogren advantage—where simple ideas shape extraordinary solutions.

Head Back to the Main Product Page

Light Duty Pullers

See some of our satisfied customers

M-Series Vaughn Puller FAQ

Are Sjogren’s Heavy Duty Pullers compatible with Morgan-style assemblies already in my facility?

Yes, these pullers seamlessly integrate into Morgan-style systems, minimizing integration downtime.

What is the recommended maintenance schedule for M-Series pullers and parts?

Recommended Product Maintenance Schedule

Jaw Type Material Frequency Morgan Low Carbon 9 Months Medium Carbon 6 Months High Carbon 3 Months Non-Ferrous 12–18 Months Maintenance is essential to avoid unplanned downtime! See the above chart for recommendations. This is also dependent on how often these are being used. Heavy usage will impact how long the parts will last.

Contact us with your model number and wire specs for custom options. You can use the contact form at the bottom of this page or you can email our team directly at sales@sjogren.com.

Are replacement parts readily available?

Yes, we aim to stock all standard replacement parts, including jaws and springs for quick shipping and easy installation.

Our average lead time is 2 weeks for standard items, but aim to stock commonly replaced items so they can ship out within 1 business day!

Are these pullers suitable for high-tension wire drawing processes in industries like mining or aerospace?

Absolutely.

Our heavy-duty pullers handle high-tension wire pulling common in mining, aerospace, automotive, and construction applications, maintaining consistent performance under intense operational conditions.

What do these models cost?

Our products are made of the highest quality materials, with precision engineering.

We do offer volume pricing on almost all of our products, so take this into consideration when requesting quotation!

It costs our manufacturing line less to produce 5 or more of a product than it does to produce 1 in one run, and we share these savings with you.

Do the replacement jaws have options for specialty tooth patterns for unique industrial applications?

Yes, our jaws offer both standard and custom diamond or straight tooth patterns, enabling secure gripping and minimizing slippage even on specialty or coated wires and high-tensile rod.

Get Your Custom Puller Quote – Fast & Reliable Pricing and Delivery!

Tell us your puller head, pulling dog, assembly, chain, or parts needs, and our team will provide a tailored quote quickly. Get the best solution for precision wire straightening today!