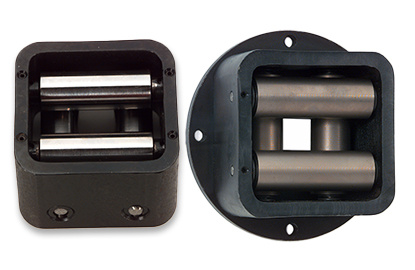

Inlet Guide Roller Boxes

Product Overview

Sjogren’s Inlet Guide Roller Box series, meticulously designed for cabling and machine entry guide applications, offers a reliable and efficient solution to marking issues. Equipped with durable hardened steel rollers, these low-maintenance units come in a wide range of sizes to suit your precise requirements.

By enabling wire to roll smoothly into the drawing machine, Inlet Guide Roller Boxes minimize marking or scratching. Sjogren’s roller boxes are fully compatible as replacements for worn units from other manufacturers.

Key Benefits

Explore the essential features of our Roller Box series inlet guides through our interactive model, or scroll down to access detailed technical specifications, including precise measurements and information.

1 Cost-Effective Rollers

2 Rugged Base

3 Collar Shaft

4 Easy Installation

5 Low Friction Rollers

Why Choose Sjogren's Inlet Guide Roller Box?

1. Multi-Roll

2. Shaft Safety

3. Eliminate Marking

4. Four Models

Industries and Applications

The Sjogren Roller Boxes are trusted by major players in these industries and many more:

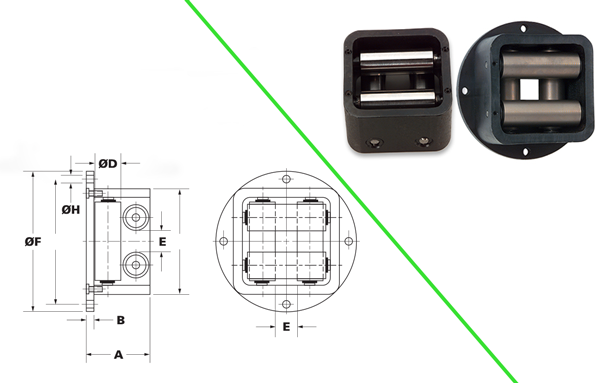

Product Measurements and Technical Specifications

Roller Box Technical Specifications

View RB Models And Measurements

RB 5M

Part # 338444-01RB 10M

Part # 338320-02RB 20M

Part # 447697-00RB 30

Part # 447648-00Wire Diameter up to .197″

up to 5 mmup to .394″

up to 10 mm.394″-.787″

10-20 mm.394″-1.181″

10-30 mmA 1.44″

36,6 mm2.68″

68 mm3.70″

94 mm5.42″

137 mmB .19″

4,8 mm.31″

8,0 mm.31″

8,0 mm.5″

12 mmC 2″

51 mm4″

102 mm5.5″

140 mm8″

203 mmDiameter D .5″

12,7 mm1.102″

28 mm1.496″

38 mm1.875″

48,5 mmE .433″

11 mm.787″

20 mm1.260″

32 mm2.953″

75 mmDiameter F 3″

76 mm5.31″

135 mm7.5″

190 mm11.81″

300 mmG 2.520″

64 mm4.724″

120 mm6.693″

170 mm10.433″

265 mmDiameter H .220″

5,6 mm.276″

7,0 mm.281″

7,0 mm.359″

9,6 mm

Download the Application Data Sheet

Complete the Application Data Sheet to engage our expert engineering team today and implement Sjogren quality straighteners into your production!

See some of our satisfied customers

Roller Box Inlet Guide FAQ

Will the RB be compatible with my unit from a different manufacturer?

Yes! We have designed our inlet guides to completely align with any comparable inlet guide and any machine to ensure your worn model is replaced with Sjogren quality, worry free.

Why rollers on the inlet guide?

Sliding wire from coils into drawing machines causes more friction, and with friction comes marking. The rollers allow the wire to roll, rather than slide, into the machine, keeping friction at a minimum, and your wire in top shape.

What if our rollers seize?

Depending on your production and lubrication, it is possible that with time the rollers will get “gunked up”. Regular, planned preventive maintenance is essential to maintaining your roller guides. They are built to last, and we are here to assist with troubleshooting and replacement as needed.

What are some common signs of wear to stay ahead of unplanned downtime?

Look for an amber color on your roll. This indicated the temperature has reached 450 to 500°F/ 232°C to 260°C. This is a sign of bearing failure. Keep a thermometer nearby to check weekly on high-intensity productions.

Keep your lubricants at bay. Ensure a regular cleanup between new coils, or every shift to ensure longevity.

What do these Roller Boxes cost?

Crafted from premium materials and engineered with precision, our products stand out for their durability, often outlasting typical wire guides by double.

The longevity and reliability of our products offer unmatched value. Additionally, we provide volume pricing on nearly all items, allowing you to benefit from cost efficiencies when ordering in bulk.

Our production process is optimized to reduce costs when manufacturing five or more units in a single run, and we share these savings with you.

Get Your RB Inlet Guide Quote – Fast & Reliable Pricing And Delivery!

Tell us your wire processing needs, and our team will provide a tailored quote quickly. Get the best solution for consistent wire drawing today!