SDR | Static Dancer Roll

Product Overview

The Static Dancer Roll replaces the conventional dancer roller or tuner roller on a wire drawing machine as the ultimate wire guide solution.

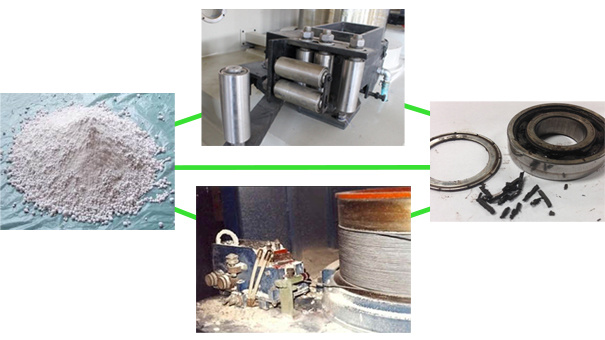

With the conventional roller, the combination of high heat, draw lube contamination, and general wear causes wire surface scratching, ball bearing seizure, and constant maintenance. This is all eliminated with our SDR!

Key Benefits

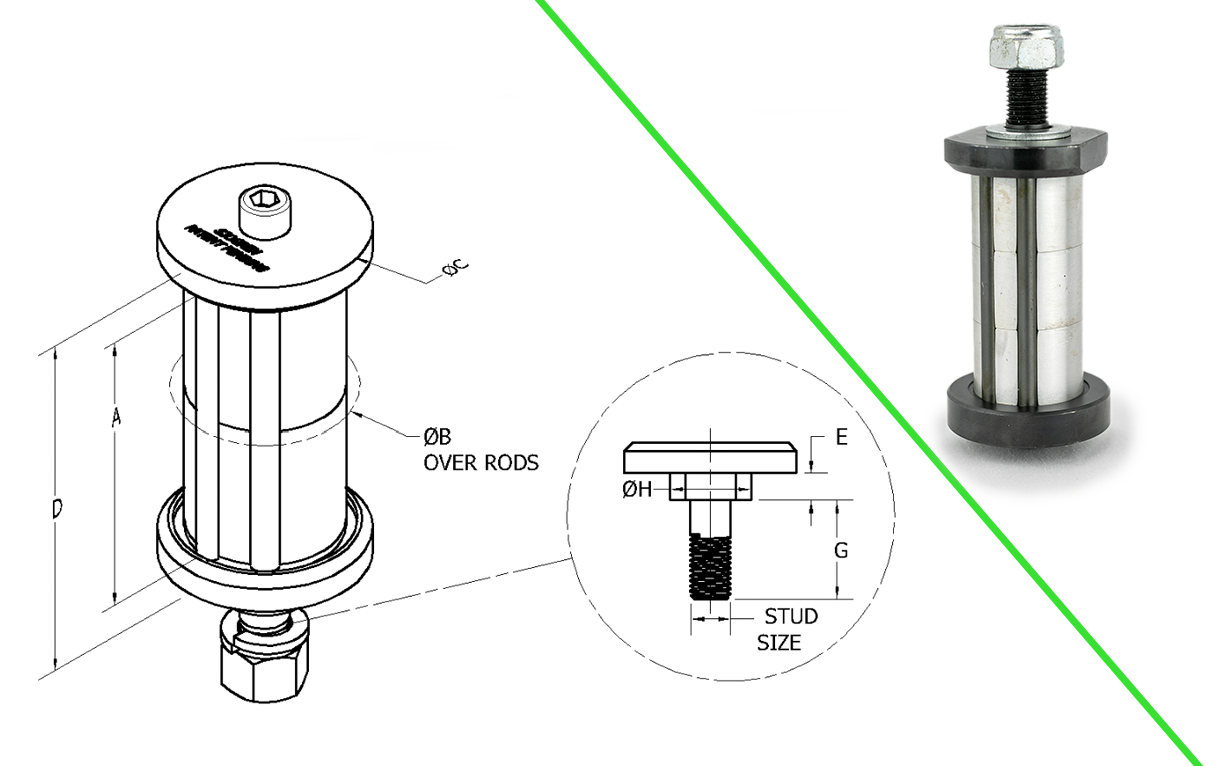

see the key features of our static dancer roll with our interactive model here or jump down to technical specifications further down the page to find measurements and details

1 Lightweight

2 No Bearings

This is a huger benefit for dry drawing lubricant powders. No ball bearing wear to worry about.

3 Tungsten Carbide Rods

These rods have no wear in over 2.5 yrs of trial data.

This innovation supports extended production life and enhanced efficiency, ultimately reducing production costs.

4 Multiple Wear Surfaces

This innovative design extends the lifespan of your roller by four times on each rod! These dancer rolls are made to reduce machine downtime and maintenance costs, making your production a high-performing machine.

5 Easy Installation

One customer has stated that their machines have had the Static Dancer rolls for over 18 months without any operational downtime to manage them.

"The static rolls save your wire mill money, downtime and improves the quality of your wire."

Why Choose Sjogren's Static Dancer Roll?

1. Multi-Application

2. No Bearings, No Problems

3. Stackable Aluminum bodies

4. Spindle Uptime

Industries and Applications

The Static Dancer Roll is trusted by major players in:

Product Measurements and Technical Specifications

Static Dancer Roll Technical Specifications

View SDR Models And Measurements

Part

NumberA B ØC D E G ØH STUD

SIZE228406-00 4″

101,6 mm2.25″

57,2 mm2.65″

67,3 mm4.94″

125,5 mm0.56″

142 mm1.37″

34,8 mm1.25″

31,8 mm*M16 228406-01 8.00″

203,2 mm2.25″

57,2 mm2.65″

67,3 mm8.94″

22,7 mm.08″

2 mm1.54″

39,1 mm.98″

24,9 mmØ.787

20 mm228463-00 3.00″

76,2 mm1.57″

40 mm2.16″

54,9 mm3.87″

98,3 mm– 1.24″

31,5 mm– *M14 228463-01 4.00″

101,6 mm1.57″

40 mm2.16″

54,9 mm4.87″

123,7 mm– 1.24″

31,5 mm– *M14 228463-02 4.00″

101,6 mm1.57″

40 mm2.16″

54,9 mm4.87″

123,7 mm0.382″

9,7 mm0.839″

21,3 mm0.629″

15,97 mm*M12 228406-03 4.00″

101,6 mm2.25″

57,2 mm.2.65″

67,3 mm49.4″

125,5 mm0.91″

23,1 mm1.59″

40,4 mm1.181″

30 mm*M24 228517-00 .92″

23,3 mm1.31″

33,4 mm1.37″

34,8 mm2.37″

60,2 mm– .79″

20 mm– M8

BOLT228478-00 1.00″

25,4 mm1.38″

35 mm1.5″

38,1 mm2.69″

68,3 mm– 1.12″

28,5 mm– *M8 228478-01 1.00″

25,4 mm1.38″

35 mm1.5″

38,1 mm2.56″

65 mm– .48″

12,3 mm– *M12 338992-00 4.00″

101,6 mm2.95″

75 mm3.34″

84,8 mm5.12″

130 mm.276″

7 mm1.5″

38,1 mm1.18″

30 mm*M10F 448421-00 6.89″

175 mm4.72″

120 mm5.51″

140 mm7.84″

198.3 mm– 2.33″

59,2 mm– **M8F 228567-00 3.74″

95 mm1.46″

37 mm2.16″

54,9 mm4.46″

113,3 mm– 1.24″

31,5 mm– *M14 228578-00 1.856″

47,15 mm0.846″

21,5 mm1.11″

28,2 mm2.53″

64,2 mm– 0.590″

15 mm– Ø0.34″

Ø8,64 mm*NUT INCLUDED F=INTERNAL THREAD **2 HOLES ON Ø.787 (20MM)B.C.

Connect With A Specialist

Complete the Application Data Sheet to engage our expert engineering team today and implement Sjogren quality into your production!

See some of our satisfied customers

Static Dancer Roll FAQ

Will the wire scratch because the roll is not rotating?

Conventional rollers typically are not rotating at the wire linear speed. With this speed differential, scratching is more likely to occur. As the bearing starts failing or seizing the problem becomes even more severe. The SDR eliminates this potential.

How do I order replacement rods to stay ahead of downtime when the time comes?

Breakdown on rods is heavily dependent on your use and environment, but it will take quite a while before needing replacement. Before replacement of the rods, ensure you have rotated the rods to a fresh round side. This will allow at least 4 times the longevity.

Contact us with your model number and wire specs for custom options or replacement rods. You can use the contact form at the bottom of this page or you can email our team directly at sales@sjogren.com.

Won't the carbide scratch because it isn't rotating?

Conventional rotating rollers typically feature a surface finish of 16µ (micron) and a hardness of 60/62 RC.

In contrast, our tungsten carbide rods boast an impressive surface finish of 1µ (micron) and a hardness of 80 RC. This results in a surface finish that is significantly superior to conventional rolls and approximately 35% harder.

These rods are highly resistant to scratching, even under substantial force.

What happens if the carbide rod starts to show marks from wear?

Our extensive 2.5-year test trials reveal no noticeable wear on the Static Dancer Roll. Should wear become evident and you feel uneasy, the carbide rods can be swiftly adjusted to a fresh surface in under a minute by simply loosening the cap and screw, then rotating each rod.

What do these SDRs cost?

Crafted from premium materials and engineered with precision, our products stand out for their durability, often outlasting typical wire guides by at least four times.

While our initial costs may be higher, the longevity and reliability of our products offer unmatched value. Additionally, we provide volume pricing on nearly all items, allowing you to benefit from cost efficiencies when ordering in bulk.

Our production process is optimized to reduce costs when manufacturing five or more units in a single run, and we share these savings with you.

How do we adapt these non-rotating rolls into our machines?

We handle everything for you! Just complete the application data sheet, share with us at sales@sjogren.com, and after our evaluation, the SDR will be provided for seamless installation on your machine, requiring no engineering assistance.

Get Your Static Dancer Roll Quote – Fast & Reliable Pricing and Delivery!

Tell us your wire processing needs, and our team will provide a tailored quote quickly. Get the best solution for consistent wire drawing today!