Reverse Bend Tester

Product Overview

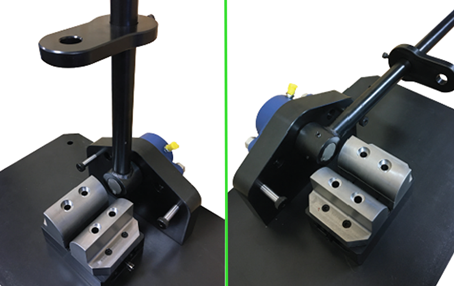

The Reverse Bend Tester is used in the wire industry to determine the ability of metallic wire, coated metallic wire, and flat strip to undergo plastic deformation during reverse bending.

The RBT from Sjogren provides a simple solution to the bend testing process. It is operated by pivoting the bending arm back and forth 90˚ while the material being tested is positioned in adjustable jaws and sample supports.

This will test cracking or deformation of the coating on the wire to ensure quality is up to your specifications and the RBT from Sjogren was designed based on ISO standards for metallic material testing.

Key Benefits

Discover the key features of the Reverse Bend Tester using our interactive model, or scroll down to explore more about the quality testing standard in reverse bending and standard model options.

1 Compact and Lightweight

Designed to be compact and fit on any work surface, the Reverse Bend Tester size is perfect for mounting at a work site or on a separate pedestal using four M10 bolts.

Dimensions:

- Width: 12"

- 305 mm

- Length: 20"

- 508 mm

- Height: 6" not including arm

- 153 mm not including arm

- Weight: 80 lbs.

- 36 kg

2 Self-Centering Base Clamp

3 Sample Guides

4 Rugged Construction

5 Interchangeable Supports

Why Choose Sjogren's Reverse Bend Tester?

1. Manual Operation

2. Leverage

3. Reliable Results

4. No Power Required

Industries and Applications

The Sjogren Reverse Bend Tester is trusted by major players in many industries that require quality assurance including:

Product Ranges For The Reverse Bend Tester

View The Models Available And Standard Support Guides

Part Number Wire Range 448552-00 Base Unit (w/o supports & guide) 886641-01 Support/Guide for Ø0,3-0,5mm wire 886641-02 Support/Guide for Ø0,5-0,7mm wire 886641-03 Support/Guide for Ø0,7-1,0mm wire 886641-04 Support/Guide for Ø1,0-1,5mm wire 886641-05 Support/Guide for Ø1,5-2,0mm wire 886641-06 Support/Guide for Ø2,0-3,0mm wire 886641-07 Support/Guide for Ø3,0-4,0mm wire 886641-08 Support/Guide for Ø4,0-6,0mm wire 886641-09 Support/Guide for Ø6,0-8,0mm wire 886641-10 Support/Guide for Ø8,0-10,0mm wire

Connect With A Specialist

Work with our team of wire tooling experts to determine the ideal part for you, or let us know which you need! Our team is here to support your production in any way we can.

See some of our satisfied customers

Reverse Bend Testing FAQ

How do I know what length to test of my wire or strip?

Length and testing requirements will be set by you or your customer. The wire or strip being tested should be the straightest possible as to not sway any results.

What if my test piece is not straight?

A test piece that is not completely straight is going to impact your results. It is recommended to straighten your test pieces completely using either a wire straightener, or going the tried and true way of hammering on a level surface such as wood, plastic or copper, and a hammer of similar material. The hard part this way is ensuring the test piece isn’t damaged or twisted!

How do I ensure the best outcome for my reverse bend test?

Ensure that your test piece is placed properly in the guides, and grips, and you bend the piece completely 90° in each direction, each interval per your testing requirements.

One direction completely bent and back to its original position is considered one bend.

Repeat in the opposite direction without interruption

What does the Sjogren RBT cost?

Sjogren stands out in the market with unparalleled quality. Our pricing is tailored to your specific production requirements.

We offer volume pricing discounts, sharing the savings from manufacturing larger quantities directly with you. Consider this for bulk orders of different sizes.

Depending on material costs, a RBT may cost generally under $20k, often much less. All Sjogren products come with Sjogren’s quality assurance guarantee for life and comprehensive support for all your wire tooling and quality testing needs.

What are the wire diameter or flat wire ranges the RBT can manage?

We offer a range of standardized guides to accommodate wire diameters from 0.012” – 0.394” (0,3mm-10mm) and metallic flat wire 0.118” (3mm) thick or less.

Get Your Reverse Bend Tester Quote – Fast & Reliable Pricing And Delivery!

Tell us your wire processing needs, and our team will provide a tailored quote quickly. Get the best solution for consistent wire drawing today!