Torsion Twist Tester

Product Overview

Sjogren’s Torsion Twist Tester is available in three distinct models, each designed to cater to a broad spectrum of testing needs. It offers 12 customizable twisting programs, complete with cycle memory, ensuring comprehensive testing. Ideal for assessing brittleness, inclusions, hidden seams, and other defects, this tester is essential for evaluating high carbon steel wire or copper/aluminum rods.

The Torsion Twist Tester meticulously rotates a wire sample around its center to evaluate brittleness, inclusions, hidden seams, and other imperfections. Available in three models accommodating wire diameters from .010″ to .750″ (0.2mm to 19mm), it empowers your quality testing team to achieve faster, more efficient, and assured results.

Key Benefits

Discover the key features of the Torsion Twist Tester using our interactive model, or scroll down to explore more about the quality testing automation standard in the wire industry from Sjogren Industries!

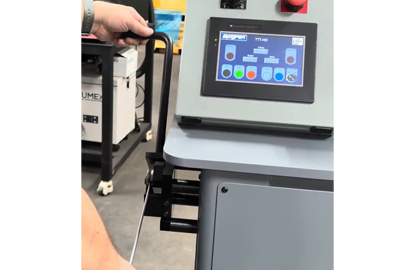

1 Programmable

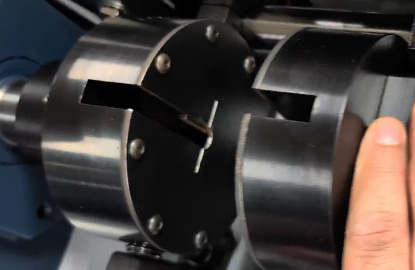

2 Holding Chucks

3 Semi-Automatic

4 Angle Bender (optional)

5 Linear Weight

The weight is dependent on the strength of the material and the test specifications.

6 Models for Any Strength

Why Choose Sjogren's Torsion Twist Tester?

1. Reliability

2. Options

3. Visibility

4. Flexibility

Industries and Applications

The Sjogren Torsion Twist Tester is trusted by many industries that require quality assurance including:

Product Ranges For The Torsion Twist Tester

View The Standard Tooling Block Arrangements

Specs LD Model MD Model HD Model Power 1/3 HP 220V; 3 Amp; 1 PH, 60Hz 1 Hp, 220 VAC; 5 Amp; 1 PH, 50/60 Hz 1-1/2 HP 220V; 10 Amp; 1 PH, 60Hz Wire Range .010″ to .090″

0,25 mm to 2,3 mm.15″ to .375″

3,81 mm to 9,53 mm.090″ to .312″

2,3 mm to 8,0 mmMax Tensile Strength 450,000 PSI

(3100 Mpa)70,000 PSI (483 Mpa) Copper or aluminum 450,000 PSI (3100 Mpa) or with extended capacity up to .375″ (9,5 mm) dia. material at 220,000 PSI (1860 Mpa) Sample Length Capacity 2″ to 15″

0,50 mm to 380 mm6″ to 20″

152 mm to 500 mm6″ to 24″

150 mm to 610 mmMax Operating Speed 120 RPM 60 RPM 30 RPM Machine Width 56″

1422 mm56″

1422 mm56″

1422 mmMachine Depth 27″

685 mm27″

685 mm27″

685 mmMachine Height 50″

1270 mm50″

1270 mm50″

1270 mmWorking Height at

Centerline of Wire39″

1000 mm39″

1000 mm39″

1000 mm

Connect With A Specialist

Work with our team of wire tooling experts to determine the ideal part for you, or let us know which you need! Our team is here to support your production in any way we can.

See some of our satisfied customers

Torsion Twist Tester FAQ

Is there a benefit to running the test in reverse?

The Torsion Twist Tester is completely programmable to any test specifications. The option to reverse and forward the twist is completely dependent on your customers test specifications. The reverse can show any deformation after being twisted in one way, confirming if any breaks or inclusions were inflicted during the forward twist.

Do my test parameters stay loaded in the programmable display?

Your parameters will stay on the machine until you select the option to reset your test settings.

What does the home button do?

The home button indexes the rotating chuck to standard setting so you can reload it with a new material, or bring it back to the beginning setting of the test.

What does the Sjogren TTT cost?

Sjogren stands out in the market with unparalleled quality. Our pricing is tailored to your specific production requirements.

Depending on material costs and your requirements and added features, a Torsion Twist Tester generally costs roughly in the mid $40k range.

All Sjogren products come with Sjogren’s quality assurance guarantee for life and comprehensive support for all your wire tooling and quality testing needs.

What if my jaws are not gripping my test material?

Sjogren is here to help! We offer custom and standard jaw replacements. Reach out to the team using the form below or email sales@sjogren.com to provide us your jaw details.

Get Your Torsion Twist Tester Quote – Fast & Reliable Pricing And Delivery!

Tell us your wire processing needs, and our team will provide a tailored quote quickly. Get the best solution for consistent wire drawing today!