Forney and United Tensile Testing

Product Overview

As a leading provider of tensile testing consumables, we proudly support OEM manufacturers like Forney Testing Equipment and United Testing Systems.

Sjogren’s precision-engineered replacement jaws are designed to perfectly fit your Forney or United testing equipment, enabling your team to make informed decisions with accurate data, and the highest quality aftermarket testing tools on the market.

Sjogren has developed a proprietary tooth pattern that provides absolute unmatched durability and grip while ensuring compatibility with your current machinery.

We are your go-to supplier for all Forney and United testing jaws for their respective advanced material tensile testing machinery lines.

Key Benefits

Sjogren’s tensile testing products are world-renowned for their quality and durability. The aftermarket jaws for United Testing machinery and Forney equipment are unmatched in the industry.

Explore a jaw from our Forney line using our interactive model to get a better understanding of the quality that goes into Sjogren’s tensile testing tooling line.

Scroll down to access detailed technical specifications and identify your model for our complete tensile testing line offerings.

1 Completely Compatible

With our precision engineering, each jaw is designed to meet your specifications and ensure a perfect fit with your machinery, with zero opportunity to influence your testing data.

2 Precision Cut

Sjogren Industries' tensile tooling is meticulously crafted for resilience, including the Forney-Style Waffle pattern model.

This is your testing, your quality control, executed on your terms, and always meeting the highest quality standards—guaranteed.

3 Yours, Truly

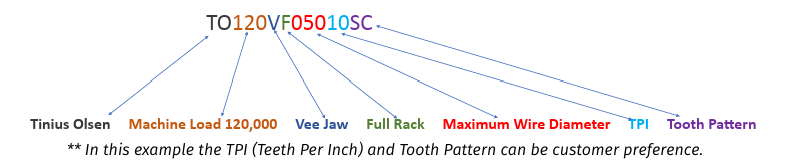

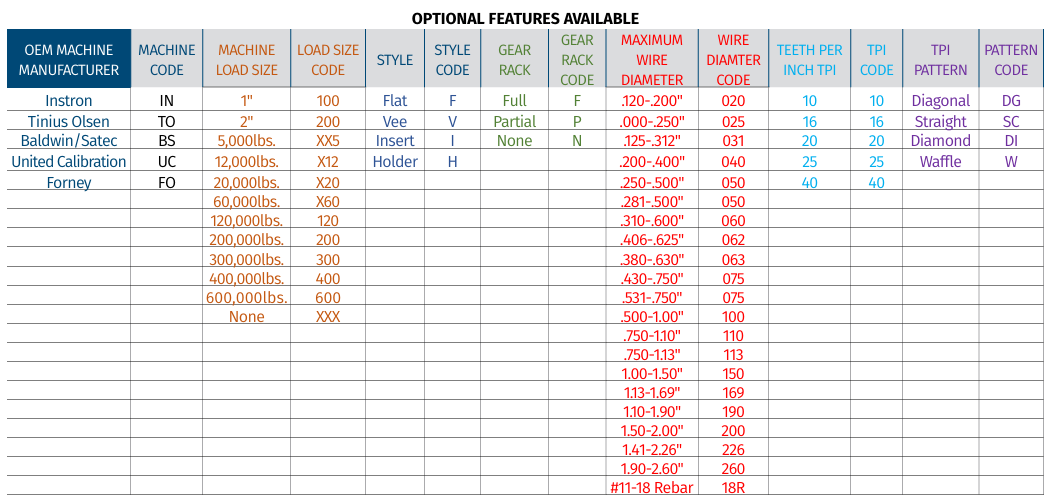

This 17-digit part number encapsulates the complete specifications of your material. Each SPN is laser etched onto your product, ensuring effortless identification for you and seamless replication for us whenever replacements are needed.

4 Load-Ready

Our tensile testing tooling line features meticulously engineered hardened steel, is crafted from the highest quality material available.

This guarantees durability, superior grip, reduced slippage, and precise testing outcomes, unaffected by the accessories themselves.

5 Teeth

This innovation has earned the trust of the foremost GLOBAL automotive and aerospace companies, who rely on Sjogren-branded tensile testing jaws for their most demanding and CRITICAL spring applications, specifically when we speak of quality testing. You can choose your teeth per inch, ranging from 10TPI to 50TPI

How Does The Smart Part Numbering System Work For Tensile Testing Accessories?

Industries and Applications

Sjogren’s tensile testing products are trusted worldwide by manufacturers in virtually any industry that tests their wire and steel material for quality and tensile capacity:

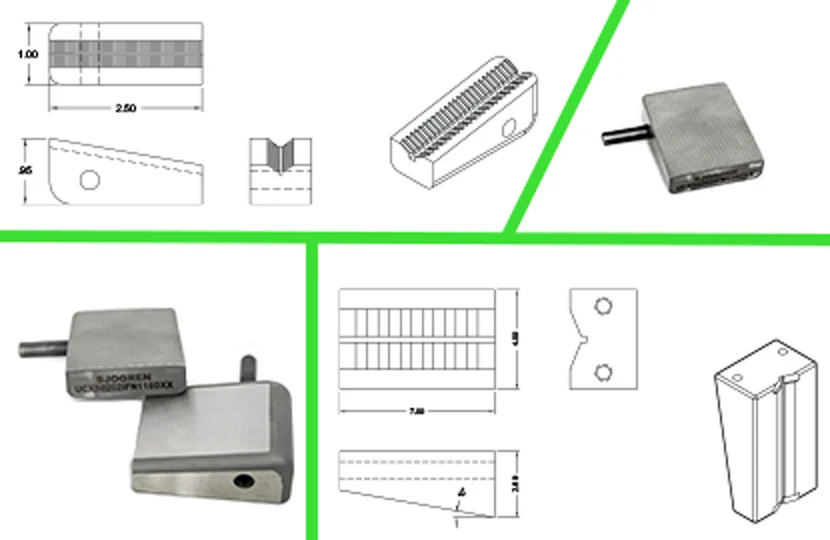

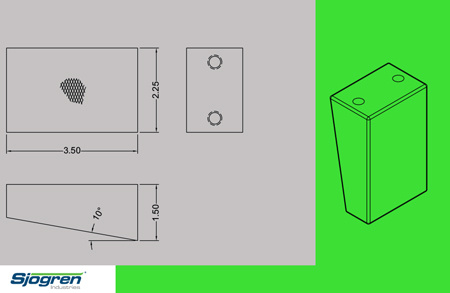

Product Measurements and Technical Specifications

Find More of our Tensile Testing Product Line within our Tensile Testing Catalog here and a sample of our jaws below.

If you don't see your model, we can still make it! Send us samples, reach out with the form below!

Forney and United Testing Style Jaws

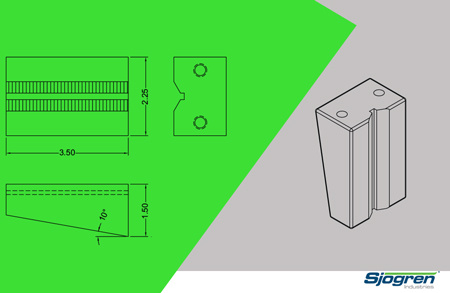

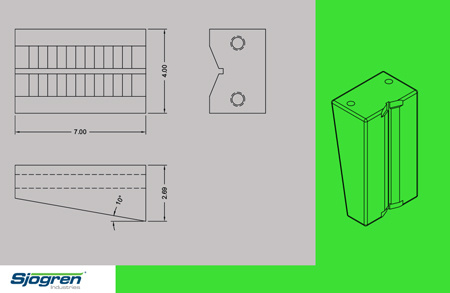

View Forney-Style FLAT Jaw for 2 1/4" Model

Base

NumberDescription FOXXX225IFN1 2-1/4″ FLAT JAW View Forney-Style VEE Jaw for 2 1/4" Model

Base

NumberDescription Wire

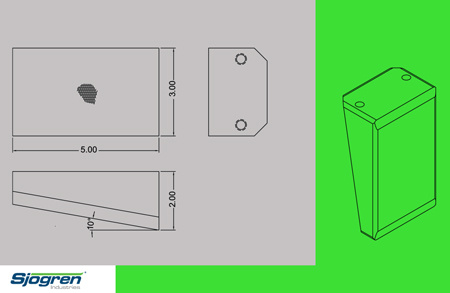

RangeFOXXX225IVN1 2-1/4″ VEE JAW .13 – .31″ View Forney-Style FLAT Jaw for 3" Model

Base

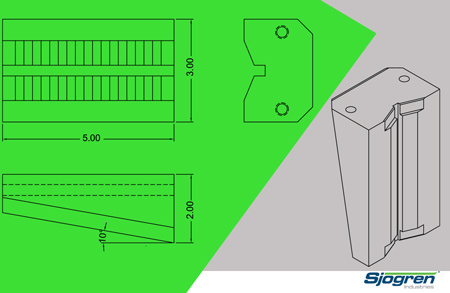

NumberDescription FOXXX300IFN1 3″ FLAT JAW View Forney-Style VEE Jaw for 3" Models

Base

NumberDescription Wire

RangeFOXXX300IVN1 3″ VEE JAW .25″ – .75″ FOXXX300IVN2 3″ VEE JAW .75″ – 1.13″ FOXXX300IVN3 3″ VEE JAW 1.0″ – 1.5″ View Forney-Style FLAT Jaw for 4" Model

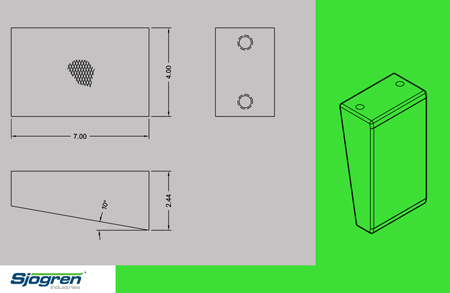

Base

NumberDescription FOXXX400IFN1 4″ FLAT JAW View Forney-Style FLAT Jaw for 4" Models

Base

NumberDescription Wire

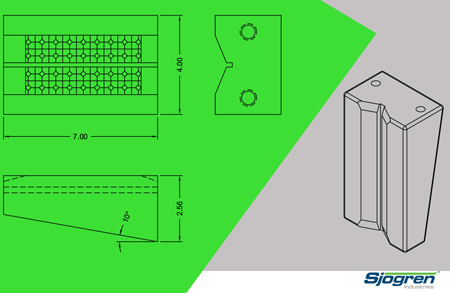

RangeFOXXX400IVN1 4″ VEE JAW .25″ – .75″ FOXXX400IVN2 4″ VEE JAW .75″ – 1.13″ FOXXX400IVN3 4″ VEE JAW 1.0″ – 1.5″ View Forney-Style VEE Jaw for 4" Waffle Pattern Model

Base

NumberDescription Wire

RangeFOXXX400IVW1 4″ VEE JAW #11 – #18

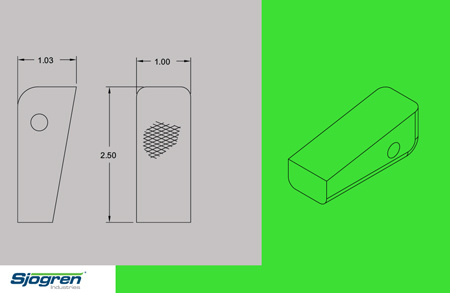

REBARView United Calibration-Style FLAT Jaws for 1" Models

Base

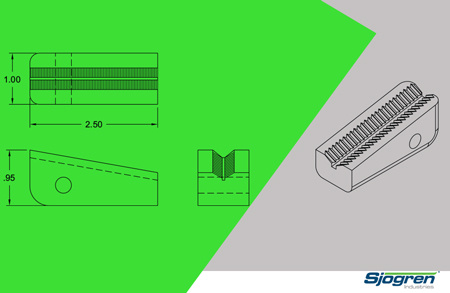

NumberDescription UCXXX100IFN1 1″ FLAT JAW View United Calibration-Style VEE Jaws for 1" Models

*Sample Required

Base

NumberDescription Wire

Range*UCXXX100IVN1 1″ VEE JAW *Sample Required

Get the Application Data Sheet

Our team of experts is here for you. Let us know about your testing application and any applicable data about your testing machine and we will provide you with your quote and associated smart part number!

See some of our satisfied customers

Tensile Testing FAQ

What are your minimum order quantities?

All of our tensile testing jaws, inserts, and holders are manufactured in sets of four. when you order a quantity of 1, you will be purchasing a set of four jaws, or four inserts, or four holders.

What are your lead times for tensile testing products?

Sjogren is proud of our nimble ability to offer the fastest lead time in the industry. You can expect an average of two – five weeks, especially for these hardened products that go through a heat-treating process.

Knowing this will allow you to order ahead of your inventory.

What do tensile testing accessories cost?

Our tensile testing lines are highly competitive and they last more than twice as long as our competitors thanks to our enhanced production equipment and expert engineering. We have set pricing on most of our tensile testing line across the board, generally within $500-$1500 per set depending on your specific customizations.

All pricing is subject to change dependent on steel and other metal market pricing.

Get Your United/Forney Replacement Jaws Quoted Today– Fast & Reliable Pricing And Delivery!

Tell us your wire processing needs, and our team will provide a tailored quote quickly. Get the best solution for consistent wire drawing today!