Hysteresis Tensioning Brakes

Product Overview

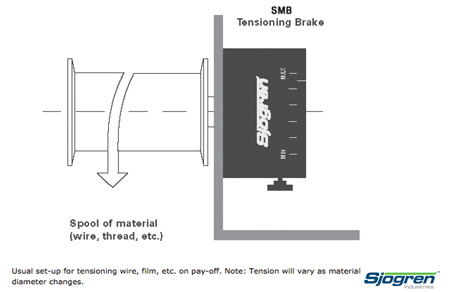

Sjogren’s magnetic brakes for spooling and winding operations are key for any wire production facility. By helping control torque variations, tensioning brakes preserve drive train life in winding operations.

Utilizing magnetic resistance (hysteresis), Sjogren’s brakes operate without the need for an external power source and are designed with minimal mechanical wear components, aside from ball bearings.

The primary applications include: material unwind operations for payoff tasks; coil-wind operations ensuring constant tension with a nip roll; material handling for electric motor overload protection; and tightening operations for consistent cycling and tightening.

Key Benefits

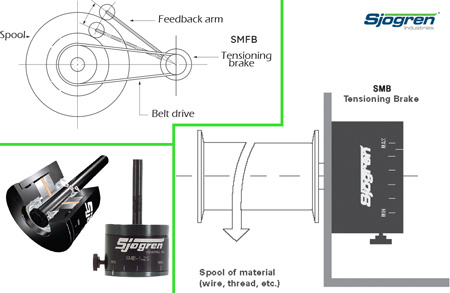

Discover the key features of the Hysteresis Brakes from Sjogren with our interactive model or scroll down to explore more about the options available, including tensioning feedback brakes and eddy-current clutches!

1 Mechanical Assembly

2 Consistency

3 Repeatability

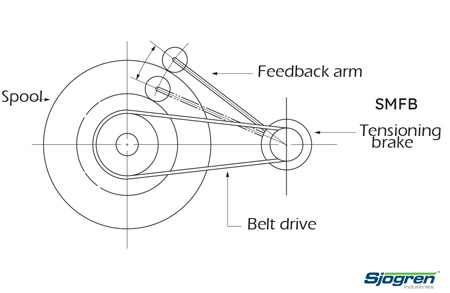

4 Feed-back Tensioning Brake Options Available

5 Constant Tension – No External Power Needed

The rugged brakes provide constant torque regardless of the rotation speed. They ensure smooth startup and uniform movements even as the diameters change. The brakes operate according to the principle of permanent magnetic dual disks hysteresis.

Units can be used for powertrain overload protection. This magnet technology does not require an external power supply and is virtually maintenance and wear-free.

Why Choose Sjogren's Hysteresis Brakes?

1. Unwinding

2. Coil-winding

3. Overload Protection

4. Tightening Operations

Industries and Applications

The Hysteresis Brakes and Clutch line from Sjogren is trusted by many industries that require consistency and reliable repeatability:

Sjogren's Hysteresis Brake & Feedback Brake Models and Specifications

View Tech Specs and Model Options Sjogren Magnetic Brakes

Model Torque Range Max. RPM at

Min. TorqueMax. RPM at

Max. TorqueMax. Moment

on ShaftSMB-0.75 .13lbs. – .75 in-lbs. 3,000 rev/min 1,350 rev/min 2 in – lbs. SMB-1.25 M

SMFB-1.25 M0.6lbs. – 1.25 in-lbs.

0.6lbs. – 1.25 in-lbs.2,000 rev/min

1,500 rev/min800 rev/min

750 rev/min40 in – lbs.

30 in – lbs.SMB-12 M

SMFB-12 M1lbs. – 12 in-lbs.

1lbs. – 12 in-lbs.1,000 rev/min

1,000 rev/min175 rev/min

175 rev/min80 in – lbs.

30 in – lbs.SMB-25 M

SMFB-25 M2lbs. – 22 in-lbs.

2lbs. – 22 in-lbs.1,000 rev/min

1,000 rev/min250 rev/min

250 rev/min200 in – lbs.

200 in – lbs.SMB-60 M

SMFB-60 M5lbs. – 60 in-lbs.

5lbs. – 60 in-lbs.1,000 rev/min

1,000 rev/min200 rev/min

200 rev/min1,000 in – lbs.

500 in – lbs.SMB-120 M 10lbs. – 120 in-lbs. 1,000 rev/min 200 rev/min 1,000 in – lbs. SMB= models without feedback control; SMFB= models with feedback control

Further specifications and measurements available upon request

Get Your Ideal Brake With the Application Data Sheet

Utilize this handy application data sheet to provide us your specifications and our team will be able to provide a recommendation with quote with ease

See some of our satisfied customers

Sjogren's Hysteresis Brake FAQ

What brake sizes are best for material unwind operations?

Material Unwind Operations

Sizing Specifications

Full roll diameter (in.) (FD) = 6 in.

Core diameter (in.) (CD) = 4 in.

Average Tension (lbs.) (T) = 4 lbs.

Velocity (feet per min.) (V) = 100 fpmSizing Formula

Average radius (in.) = (FD+CD) / 4 = (6+4) / 4 = 2.5 in.

Torque (in. lb.) = (T) x Avg. Rad. = 4 x 2.5 = 10 in. lb.Check Tension Range

Maximum Tension = Torque x 2 / CD (10×2 / 4) = 5 lbs.

Minimum Tension = Torque x 2 / FD (10×2 / 6) = 3.3 lbs.

Slip Watts = Max. Tens. x V / 44.2 (5×100 / 44.2) = 11.3 watts

Specify: Model SMB-12Which brake sizes are best for material handling operations?

Material Unwind Operations

Motor Horsepower Method

Motor HP = 1/2 HP

Motor RPM = 1750 RPMSizing Formula

Torque (in. lb.) = HP x 63000 / RPM

1/2 x 63000 / 1750 = 18 in. lb.

Specify: Model SMB-60Which brake size is best for tightening operations?

Tightening Operations

Sizing Specifications

Slip RPM = 500 RPM

Torque = 8 in. lbs.

% Slip Time of total cycle time = 25%Sizing Formula

Watts = .0118 x Torque (in. lb.) x Slip RPM x % Slip Time

.0118 x 8 x 500 x .25 = 11.8 watts

Specify: Model SMB-60Which brake size is best for coil wind operations?

Sizing Specifications

Pulley/Nip Roll dia. (in.) (D) = 6 in.

Tension (T) = 6 lbs.

Velocity (V) = 100 fpmSizing Formula

Torque (in. lb.) = TxD / 2 = (6×4) / 2 = 12 in. lb.

Slip Watts = TxV / 44.2 = (6×100) / 44.2 = 13.6 watts

Specify: Model SMB-12If diameter is not predetermined, calculate slip watts and select a unit with a sufficient dissipation rating. Determine maximum diameter of pulley or nip roll using the following equation: Max. dia. (in.)=(12 in.lb.x2) / 6 lbs. = 4 in.

How much do Sjogren's magnetic brake offerings cost?

Sjogren stands out in the market with unparalleled quality. Our pricing is tailored to your specific production requirements.

The costs vary greatly depending on your specific needs and material costs at the time of purchase. We do offer volume pricing for almost any of our products. It is recommended to consider purchasing in quantity to realize this opportunity.

On average at the time of this question response, pricing ranges from the mid hundreds to under $5k depending on your specific model.

All Sjogren products are supplied with the Sjogren guarantee of quality and lifetime support for replacement parts, troubleshooting and re-ordering.

Get Your Magnetic Brakes Quote Started – Fast & Reliable Pricing And Delivery!

Tell us your wire processing needs, and our team will provide a tailored quote quickly. Get the best solution for consistent wire drawing today!