Contract Manufacturing

Our shop floor is equipped with cutting-edge automation, CNC machinery, and advanced laser marking capabilities. Paired with a highly-skilled workforce, Sjogren Industries’ contract manufacturing services are globally recognized for their precision in steel manufacturing.

Value of Sjogren Managing

Your Manufacturing

Your success in manufacturing is supported by your choice of the highest quality materials and state-of-the-art equipment. At Sjogren, your satisfaction is our priority, ensuring you receive the best service globally. Whether you require standard or bespoke products, Sjogren is here to make a significant difference for you.

Sjogren's Capabilities

Our extensive selection of both manual and automatic state-of-the-art metalworking machinery guarantees exceptional quality, efficiency, and durability in your production process. Supported by our expert workforce and advanced machinery, we offer comprehensive component assembly and fully integrated parts and fulfillment, eliminating the need for in-house operations. Explore the capabilities of our in-house machinery and team below!

What Equipment and Tools Are We

Working With For Your Projects?

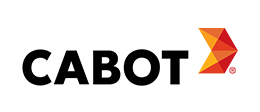

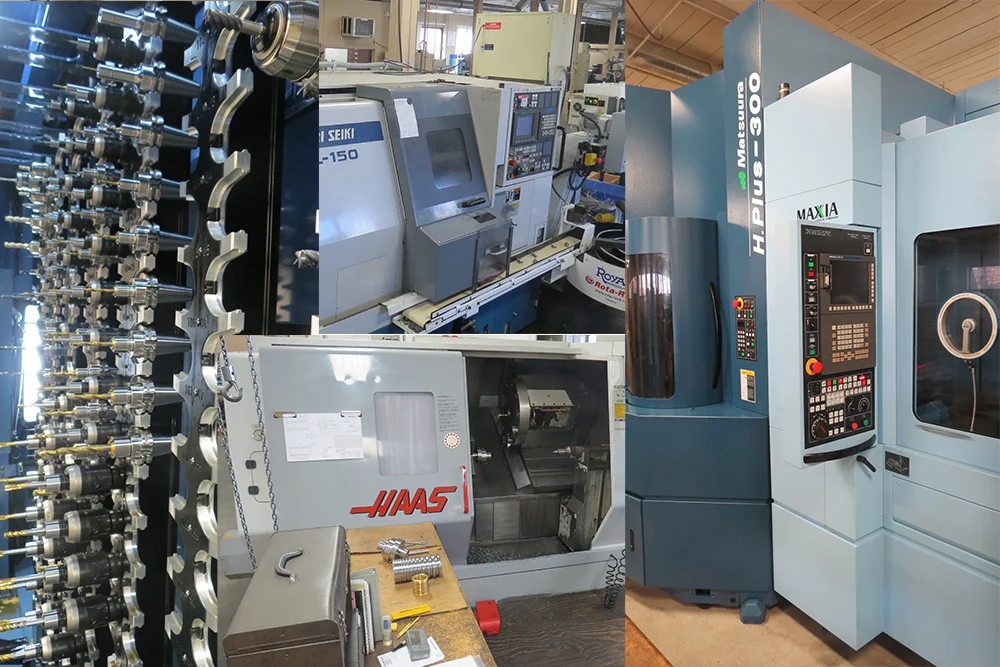

CNC-Multitask Equipment

Sjogren Industries’ CNC multitask equipment delivers complex machining precision, efficiency, and flexibility. With 6-axis capabilities and advanced “lights-out” automation, we minimize setups, reduce lead times, and ensure exceptional accuracy. Whether for intricate parts or high-mix production, our technology-driven approach guarantees consistent quality and streamlined manufacturing.

Our CNC Multitask Machinery Includes:

- Okuma MULTUS U3000 – 6 Axis

- Matsuura MAM72-35V 5-Axis

CNC Turning Equipment

With advanced automation, including robotic part handling and bar feeders, our machines maximize productivity and reduce cycle times. Featuring multi-station turrets, live tooling, and large work envelopes, they handle everything from small, high-speed precision parts to heavy-duty components up to 4,000 lbs. Whether for high-speed production, complex geometries, or large-scale turning, our CNC lathes ensure exceptional accuracy, reliability, and cost-effective operation.

Our CNC turning equipment includes:

- Shimada Twin spindle with Fanuc LR Mate 200ID Robot

- Mori Seiki SL-150

- Mori Seiki SL-25

- HAAS SL-40 Lathe

- Okuma Vertical Turning Lathe

CNC Milling Equipment

Sjogren Industries’ CNC milling equipment delivers precision, efficiency, and versatility for complex machining needs. With multi-pallet systems, large tool capacities, and Renishaw probes, our machines ensure high productivity, accuracy, and minimal downtime. From heavy-duty cutting with CAT 50 spindles to automated multi-axis machining, our advanced technology enhances speed, reliability, and quality control, making us the ideal choice for high-performance manufacturing.

Some of our CNC Milling equipment includes:

- Matsuura MC-800V Vertical Miller – 3 Axis

- OKK MCV-560 Vertical Miller – 3 Axis

- HAAS HS-2RP Horizontal Miller – 4 Axis

- Matsuura HS-300RP Horizontal Miller – 4 Axis

Tool Room Lathes

Manual turning gives our skilled operators full control over the cutting process, allowing for fine-tuned adjustments and highly accurate results, which is especially important for custom or low-volume parts.

Our Lathes include:

- Hardinge HLV-H Super Precision

- Okuma Model 21 Engine Lathe

Manual Milling Equipment

Manual mills can be quickly adapted for different jobs, making them ideal for handling unique or low-volume steel parts. This flexibility is perfect for custom orders or producing prototype components requiring specialized techniques.

Our Manual Milling Equipment Includes:

- Cincinnati Model 1-18 Production Millers

- Bridgeport EZTRACK Series 1

- Trak Trim MX2 W/Proto Trak control & Quick Change Tooling

- Bridgeport Series 1

- Lagun FTV-2 W/Proto Trak Control & Quick Change Tooling

- Moore #3 Jig Borer

Grinding & Honing Equipment

Sjogren Industries’ grinding and honing equipment offers several crucial benefits for producing high-precision, high-quality components in aerospace, automotive, and manufacturing.

Our Grinding and Honing Equipment include:

- Okamoto Surface Grinder

- Browne & Sharpe Cylindrical Grinder

- Heald Model 72A

- Sunnen Horizontal Honing Machine

- Reid Surface Grinder

- Harig Surface Grinder

Saws

These saws ensure high-quality cuts with minimal waste, reducing rework and improving the overall consistency of parts produced, which is crucial for industries that require tight tolerances and flawless end products.

Our saws include:

- DoAll Vertical Band Saw

- Marvel Horizontal Band Saw

- Severall Abrasive Cutoff

Keyence Laser Marking

Customize your parts with our Keyence 3-Axis Hybrid Laser Marker. QR codes for easy access to our sales team, and marking for part number specification are a breeze with our laser marker!

Engineering Software

We work with top-of-the-line software to design the most precise product for your production.

Some of our software includes:

- 3D Modeling with AutoDesk Inventor

- AutoCAD

- MasterCam

See and sign off on your custom tooling before we go into production, knowing its being designed by the most brilliant minds in engineering at Sjogren Industries.

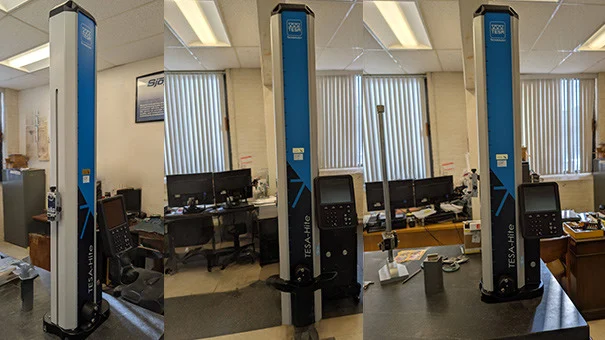

Commitment to Quality

Mitutoyo PH-3500 Optical Comparitor

J&L Metrology QBC14 Optical Comparitor

Brown & Sharpe Tesa Hite

Hardness Tester

GUHRING Quality Tool Management

Voices of Satisfaction

Our clients speak, and their satisfaction echoes. Hear their stories of collaboration, innovation, and success. Join the hundreds of customers who have experienced the value of Sjogren products.

Let’s Connect

Ready to embark on your next project with a reliable contract manufacturing partner? Let’s talk about your goals, gather quotes, or have an expert consultation with our engineers! Our team is here to support you every step of the way.