All You Need to Know About Sjogren’s Wire Guide Rollers

All You Need to Know About Sjogren’s Wire Guide Rollers

What types of wire guide rollers does Sjogren make?

Looking for wire guide rollers that will meet your specific needs? Sjogren’s wire guide rollers can be manufactured to meet your needs with high-quality materials and a durable design.

STATIC DANCER ROLL (SDR)

The Static Dancer Roll replaces the conventional dancer roller or tuner roller on a wire drawing machine. The combination of high heat, draw lube contamination, and general wear causes wire surface scratching, ball bearing seizure, and constant maintenance with the conventional roller.

Operation Problem

Spindle downtime caused by bearing failure in various rotating guides: tensioning/dancer rolls, roller boxes, traversing guides

Sjogren Innovation

Static, non-rotating guides that utilize carbide rails to provide years of functionality with minimal service

Advantages

- Lightweight

- No bearings, non-rotating

- High wear, low Friction tungsten carbide rods

- Easily installed in any application

- Extremely long life with multiple wear surfaces

- Reduces maintenance cost

- Machine downtime is reduced significantly

- Prevents wire surface damage and scratching

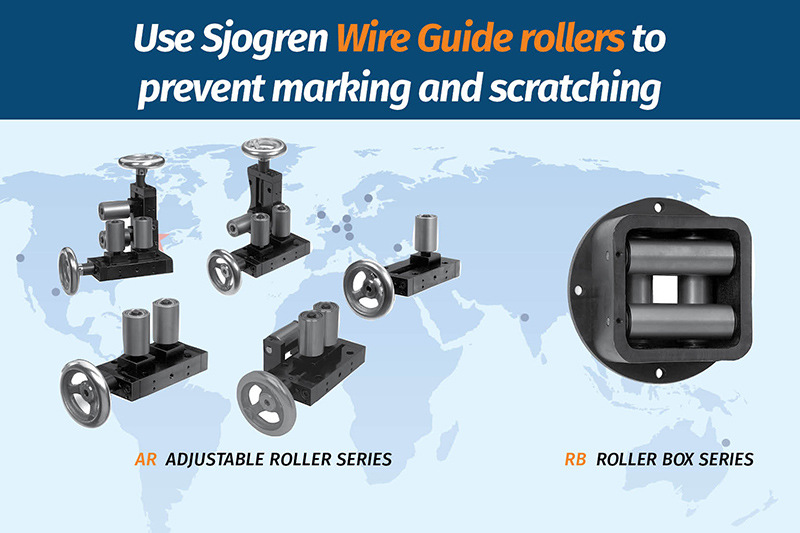

INLET GUIDE ROLLER BOXES

For cabling and other machine entry guide applications, Sjogren’s Inlet Guide Roller Boxes (referred to as the RB guide) offer a reliable, easily installed solution to marking problems. The durable hardened steel rollers are low maintenance, and the units are available in various sizes.

Hardened steel rollers are durable and resistant to wear, which could cause marking or scratching of the wire/cable material.

The flange mounting design of the shaft collar makes the unit very easy to install in many machinery configurations.

The RB guide is designed with shaft collars that eliminate bearing endplay and maintain smooth operation; no shims are ever necessary.

AR-STYLE WIRE GUIDE ROLLERS

The AR-style wire guide rollers are adjustable and have hardened steel surfaces. They are suitable for various materials and can be installed in various ways. The hand wheel adjusts both rolls simultaneously, ensuring accurate material guiding. By providing a range of configurations and roller options, Sjogren’s Wire Guide Rollers (product name: AR style) are suitable for a wide range of applications. Designed to be interchangeable as a replacement for similar style guides of other manufacturers, AR-style guides provide precision in any direction. They can be used with strip stock and shaped or round wire.

The hand wheel adjusts both rolls simultaneously, ensuring accurate material guiding a wide range of product diameters.

A single set screw per roller pair makes it easy for the wire mill or OEM operator to lock the rollers in position.

The roller surfaces are hardened steel, making them very durable and suitable for a wide range of materials; they are resistant to marking or scratching.

What are the benefits of using Sjogren’s wire guide rollers?

1. The wire guide rollers are adjustable so that you can customize the position of the wire guide.

The main benefit of using Sjogren’s wire guide rollers is the ability to adjust the position of the wire guide. This allows for a more customized experience and ensures accuracy when guiding material. The rollers are also made of hardened steel, making them resistant to marking or scratching. Additionally, the base has various mounting holes, allowing easy installation and multiple modular configurations to suit your process.

- Wire Guide Rollers are adjustable so that you can customize the position of the wire guide.

- The hand wheel adjusts both rolls simultaneously, ensuring accurate material guiding a wide range of product diameters.

- The roller surfaces are hardened steel, making them very durable and suitable to a wide range of materials; they are resistant to marking or scratching.

- The base has a variety of mounting holes, which allow for easy installation as well as multiple modular configurations to suit your process.

2. The wire guide rollers are made of high-quality materials that are durable and long-lasting.

The wire guide rollers are made of high-quality materials that are durable and long-lasting. The hand wheel adjusts both rolls simultaneously, ensuring accurate material guiding. The roller surfaces are hardened steel, making them durable and suitable for many materials. The wire guide rollers are designed to be interchangeable and provide precision guiding in any direction.

3. The wire guide rollers are adjustable in two planes, so you can use them in various applications.

The wire guide rollers offer many benefits that make them perfect for various uses. First, the rollers are adjustable in two planes, which means they can be used in various applications. Second, the hand wheel adjusts both rolls simultaneously, ensuring accurate material guiding a wide range of product diameters. Third, the roller surfaces are hardened steel, making them durable and resistant to marking or scratching. Finally, the base has various mounting holes, allowing for easy installation and multiple modular configurations to suit your process.

- The wire guide rollers are adjustable in two planes so you can use them in various applications.

- The hand wheel adjusts both rolls simultaneously, ensuring accurate material guiding a wide range of product diameters.

- The roller surfaces are hardened steel, making them very durable and suitable for a wide range of materials; resistant to marking or scratching.

- The base has a variety of mounting holes, which allows for easy installation as well as multiple modular configurations to suit your process.

4. The wire guide rollers are available in a variety of sizes so that you can find the perfect size for your needs.

The AR style guide roller is available in different sizes to accommodate different needs. The hand wheel adjusts both rolls simultaneously for accurate and consistent guiding. The roller surfaces are hardened steel, making them durable and suitable for many materials. The base has mounting holes, which allow for easy installation in multiple configurations.

What factors affect Sjogren’s wire guide rollers?

1. The type of material the wire guide rollers are made from can affect their durability and longevity.

The material of the wire guide rollers affects how durable and long-lasting they are. The rollers are made from hardened steel, which makes them resistant to damage and wear. This allows them to be used with a wide range of materials.

2. The size of the wire can affect the wire guide rollers.

The size of the wire affects the wire guide rollers because the hand wheel on the wire guide roller adjusts both rolls simultaneously. This means that if the wire is too thin, the rollers will not be able to grip it properly and may cause it to slip. On the other hand, if the wire is too thick, the rollers may not be able to turn correctly, causing them to bind up. Therefore, choosing the right size wire for your project is crucial to avoid any problems.

3. The type of installation can also affect the guides.

The wire guide rollers are adjustable and suitable for various materials. The roller surfaces are hardened steel and resistant to marking or scratching. The base has a variety of mounting holes, which allow for easy installation. The AR style guides are interchangeable and can be used with strip stock or shaped or round wire. The guides provide precision guiding in any direction.

FAQs

What are Sjogren’s wire guide rollers?

Sjogren’s wire guide rollers are designed to be interchangeable and provide precision guidance in any direction. They are suitable for many applications, including strip stock and shaped or round wire. A wire guide roller is a tool that allows for accurate material guiding. The roller surfaces are hardened steel, making them durable and suitable for many materials. The base has a variety of mounting holes, which allow for easy installation.

Sjogren’s wire guide rollers are used to help move wire guides in a controlled and consistent manner. This helps to improve the quality of your wiring by ensuring that the wires are correctly aligned and not damaged during movement.

What are the main features of Sjogren’s wire guide rollers?

The main features of Sjogren’s AR-style guide rollers include their interchangeability, which means that you can replace similar style guides of other manufacturers with these versatile guides. You can use these guides with strip stock or shaped wire, providing the perfect solution for various applications.

- These precision guides are designed to provide precise guidance in any direction and can be used with strip stock and shaped or round wire.

- The main features of Sjogren’s AR-style guide rollers include their interchangeability, which means that you can replace similar style guides of other manufacturers with these versatile guides.

- You can use these guides with strip stock or shaped wire, providing the perfect solution for various applications.

What are the benefits of using Sjogren’s wire guide rollers?

The benefits of using wire guide rollers are that they are adjustable, offer a wide range of applications, and help with accurate work. You can customize the rolling action to your specific needs by being adjustable. Additionally, because they offer a wide range of applications, they are designed to be interchangeable as a replacement for similar style guides of other manufacturers. Lastly, wire guides help ensure that your work is accurate and precise, reducing the need for reworking or redoing jobs later on down the line.

- Suitable for a wide range of applications: Designed to be interchangeable as a replacement for similar style guides of other manufacturers.

- Different versions of wire guide rollers: Different versions fit your individual needs.

- They offer adjustable roller guides: Offering adjustable roller guides allows you to customize the rolling action to your specific needs.

- These replacement wire guides help with accurate work: Wire guides help ensure that your work is accurate and precise, reducing the need for reworking or redoing jobs later on down the line.

Sjogren: delivering innovation across the full spectrum of the wire tooling industry for nine decades

Founded in 1927 by Oscar Sjogren, Sjogren Industries, Inc. has long been an innovator in designing and manufacturing customized solutions for the wire tooling trades.

Today Sjogren Industries delivers custom manufacturing, high-quality machinery, tooling, and accessories to a global customer base. The Sjogren belief that “simple ideas make better solutions” has been at the core of its innovative product designs since its inception. Sjogren continues to introduce enhancements in technology that deliver significant efficiencies and increased productivity for its customers.