EC Wire Straightener | Metric Precision, Modular Design

Product Overview

Designed as a metric counterpart to our IS (Inch Series) straighteners, the EC Wire Straightener offers precision, efficiency, and adaptability. Its modular design allows for both vertical and horizontal configurations, making it suitable for various wire and cable production processes.

Play with our interactive model here and find some of the EC straighteners key benefits.

Grab your quote now or jump down to tech specs further down the page to find your ideal model

Key Benefits

1 Locking Handles

2 Connecting Bracket For Proper Alignment

3 Quick Release Lever

4 Versatile Configuration

5 Customizable Grooved Rolls

Why Choose the EC / Metric Straightener?

1. Metric Precision

2. Modular Flexibility

3. Enhanced Durability

4. Customization

Industries and Applications

The EC Wire Straightener is trusted across multiple industries where precise wire straightening is critical, including but not limited to:

Product Configurations and Technical Specifications

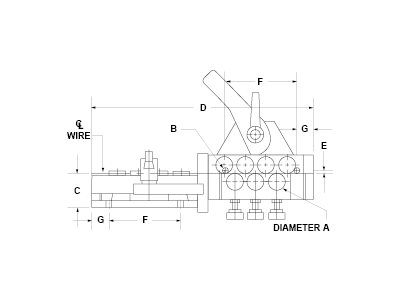

Measurements For EC Straightener Models

| Model | Diameter A | B | C |

|---|---|---|---|

| EC 10 | 10 mm | M5 | 22 mm |

| EC 13 | 13 mm | M6 | 32 mm |

| EC 16 | 16 mm | M6 | 32 mm |

| EC 22 | 22 mm | M10 | 37 mm |

| EC 23 | 23 mm | M10 | 37 mm |

| EC 30 | 30 mm | M10 | 43 mm |

| EC 31 | 31 mm | M12 | 43 mm |

| EC 32 | 32 mm | M12 | 43 mm |

| EC 35 | 35 mm | M12 | 49 mm |

| EC 40 | 40 mm | M12 | 49 mm |

| EC 45 | 45 mm | M12 | 52 mm |

| EC 52 | 52 mm | M12 | 52 mm |

| EC 80 | 80 mm | M12 | 74 mm |

Tech Specs For EC Straighteners By Model

| Model | Roll Diameter (A) | Wire Diameter Range | 2x5 Rolls (D) | 2x7 Rolls (D) | 2x9 Rolls (D) | 2x11 Rolls (D) | 2x13 Rolls (D) |

|---|---|---|---|---|---|---|---|

| EC 10 | 10 mm | 0,08 mm- 0,4 mm | 106 mm | 132 mm | 158 mm | 184 mm | 210 mm |

| EC 13 | 13 mm | 0,2 mm - 0,5 mm | 126 mm | 158 mm | 190 mm | 222 mm | 254 mm |

| EC 16 | 16 mm | 0,4 mm - 0,8 mm | 168 mm | 212 mm | 256 mm | 300 mm | 344 mm |

| EC 22 | 22 mm | 0,8 mm - 1,5 mm | 206 mm | 262 mm | 318 mm | 374 mm | 430 mm |

| EC 23 | 23 mm | 1,0 mm - 2,0 mm | 206 mm | 262 mm | 318 mm | 374 mm | 430 mm |

| EC 30 | 30 mm | 1,5 mm - 3,0 mm | 252 mm | 328 mm | 404 mm | 480 mm | 556 mm |

| EC 31 | 31 mm | 1,8 mm - 3,5 mm | 252 mm | 328 mm | 404 mm | 480 mm | 556 mm |

| EC 32 | 32 mm | 2,0 - 4,0 mm | 252 mm | 328 mm | 404 mm | 480 mm | 556 mm |

| EC 35 | 35 mm | 2,5 mm - 4,5 mm | 312 mm | 412 mm | 512 mm | 612 mm | 712 mm |

| EC 40 | 40 mm | 3,0 mm - 5,0 mm | 312 mm | 412 mm | 512 mm | 612 mm | 712 mm |

| EC 45 | 45 mm | 5,0 - 7,0 mm | 415 mm | 571 mm | 727 mm | 883 mm | - |

| EC 52 | 52 mm | 7,0 - 9,0 mm | 415 mm | 571 mm | 727 mm | 883 mm | - |

| EC 80 | 80 mm | 8,0 - 15,0 mm | 563 mm | 743 mm | 923 mm | - | - |

Download the Application Data Sheet

Fill out the Application Data Sheet to connect with our expert engineering team today and integrate Sjogren’s high-quality EC Straighteners into your production process!

See some of our satisfied customers

EC Straightener FAQ

How do I order replacement rolls to stay ahead of downtime?

You can order on our website. Fill out the form below to place your order conveniently! Alternatively, you can email our team directly at sales@sjogren.com.

What wire materials are compatible with the EC Wire Straightener?

The EC Wire Straightener is designed to process a wide range of materials, including stainless steel, aluminum, copper, and high-tensile steel.

What kind of maintenance is required for EC straighteners?

Minimal maintenance is required. The precision ball-bearing-supported rolls are greased for life, ensuring long-lasting performance. Regular inspection is recommended, and other parts are replaced very infrequently, but here is a reference guide for your rolls:

It’s all about the roll and the material you are running

Groove Type Material Replacement Frequency VEE Low Carbon 9 months VEE Medium Carbon 6 months VEE High Carbon 3 months VEE Nonferrous 12-18 months Radius Low Carbon 12 months Radius Medium Carbon 9 months Radius High Carbon 6 months Radius Nonferrous 15-21 months Is the EC Wire Straightener compatible with automated production lines?

Absolutely! The modular design allows for seamless integration into both manual and fully automated wire processing systems.

How do I know the best configuration for my operation?

Our team can assess your wire specs and recommend the ideal roll materials, groove designs, and setup for optimal performance. Contact us for a consultation!

Your straightener orientation will be selected based on your current or proposed production setup. Our straightener orientation sheet can provide visual guidance.

How does this model compare to Sjogren’s IS (Inch Series) Straightener?

Both models deliver exceptional precision in wire straightening. The EC Wire Straightener is expertly crafted for metric-based applications, while the IS Series is tailored for systems utilizing inch-based, or imperial measurements.

Get a Custom EC Series Quote – Fast & Reliable Pricing!

Tell us your wire processing needs, and our team will provide a tailored quote quickly. Get the best solution for precision wire straightening today!