Satec/Baldwin Tensile Testing

Product Overview

Satec/Baldwin machinery is globally trusted for their durable hydraulic tensile testing equipment for testing high-tensile wires, rod, springs, and other metal products.

As the leader in aftermarket supply of tensile testing consumables, we are a proud supporter of our OEM manufacturers, like Satec/Baldwin’s line of hydraulic compression and tension testing machinery.

Sjogren’s precision-engineered replacement jaws, inserts, and holders enhance your testing capabilities, empowering your team to make informed product decisions using accurate data. Our Satec/Baldwin line is designed to match your equipment with absolute assurance.

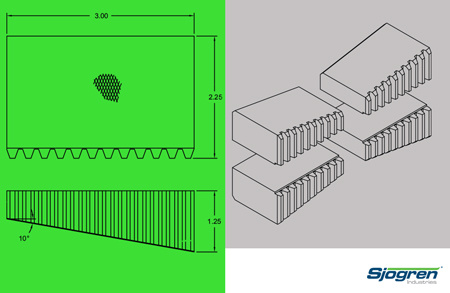

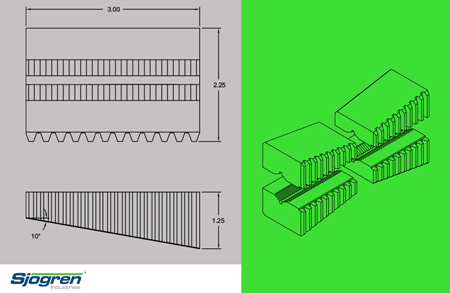

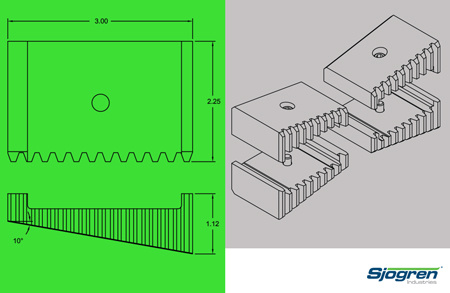

Sjogren has developed a proprietary tooth pattern that provides absolute unmatched durability and grip while ensuring compatibility with your current machinery. Find flat inserts and insert holders, flat jaws with full racks, and Vee jaws for forces ranging from 20,000 lbs. force to 600,000 lbs. force models.

* Note: we do not sell the equipment, just the tooling!

Key Benefits

Explore the Satec/Baldwin Vee-style jaw with a full rack using our interactive model. Scroll down to access detailed technical specifications for the rest of our Satec/Baldwin tensile testing accessory line, including vee shaped jaws, flat-shaped jaws, inserts, and insert holders.

1 Completely Compatible

The Baldwin/Satec replacement jaws and other tooling components are precisely engineered to meet your specifications and ensure a perfect fit with your machinery.

2 Precision Cut

Your Satec/Baldwin jaws, inserts, and insert holders are engineered for durability, capable of testing the toughest materials with some of the strongest forces in the industry, up to your specifications and quality testing requirements.

3 Yours, Truly

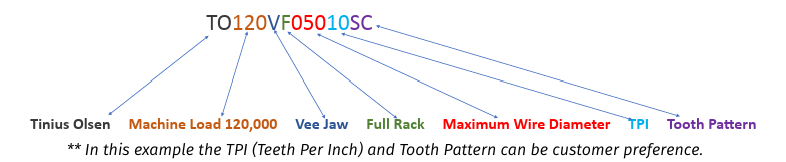

This 17-digit part number encapsulates the complete specifications of your material. Each SPN is meticulously laser etched onto your jaw, insert, and holder, ensuring effortless identification for you and seamless replication for us whenever replacements are needed.

4 Load-Ready

Our tensile testing line, featuring meticulously engineered jaws, is crafted from the most robust materials available.

This guarantees durability, superior grip, reduced slippage, and precise testing outcomes, unaffected by the accessories themselves.

5 Teeth

How Does The Smart Part Numbering System Work For Tensile Testing Accessories?

Industries and Applications

Sjogren’s tensile testing products are trusted worldwide by manufacturers in virtually any industry that tests their wire and steel material for quality and tensile capacity:

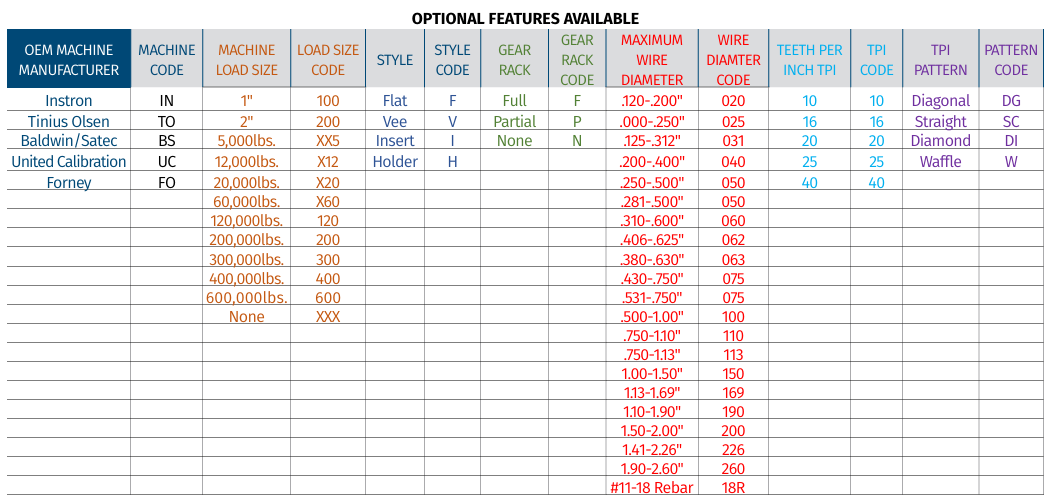

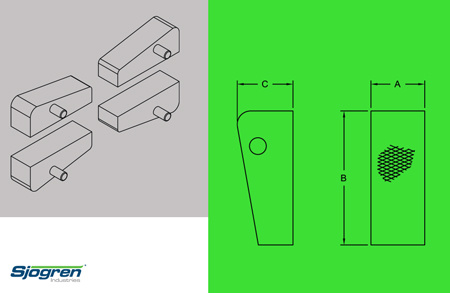

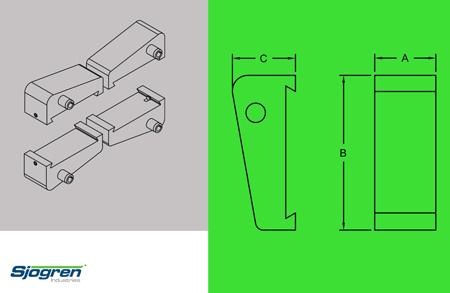

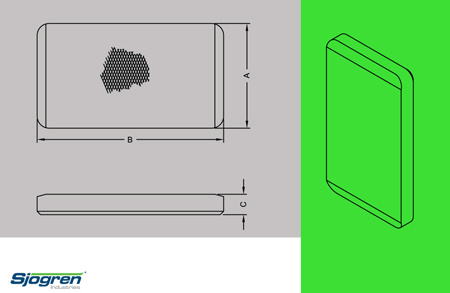

Product Measurements and Technical Specifications

Satec/Baldwin Jaws, Inserts, Holders

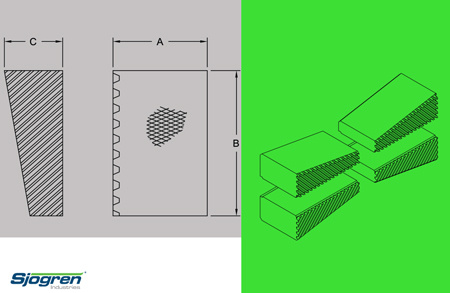

View Flat Jaws for 3/4", 1" and 2" Models

Base

NumberDescription A B C BSXXX075IFN1 3/4″ FLAT JAW .75″

19,05 mm2.38″

60,45 mm.91″

23.11 mmBSXXX075IFN2 3/4″ FLAT JAW .75″

19,05 mm2.50″

63,5 mm1.09″

27,69 mmBSXXX100IFN1 1″ FLAT JAW 1″

25,4 mm2.50″

63,5 mm1.09″

27,69 mmBSXXX100IFN2 1″ FLAT JAW 1″

25,4 mm2.50″

63,5 mm1.47″

37.34 mmBSXXX200IFN1 2″ FLAT JAW 2″

50,8 mm2.50″

63,5 mm1.34″

34,04 mmView VEE Jaws for 3/4", 1" and 2" Models

Base

NumberDescription A B C BSXXX075IVN1 3/4″ VEE JAW .75″

19,05 mm2.38″

60,45 mm.91″

23.11 mmBSXXX075IVN2 3/4″ VEE JAW .75″

19,05 mm2.50″

63,5 mm1.09″

27,69 mmBSXXX100IFN1 1″ VEE JAW 1″

25,4 mm2.50″

63,5 mm1.09″

27,69 mmBSXXX100IVN2 1″ VEE JAW 1″

25,4 mm2.50″

63,5 mm1.47″

37.34 mmBSXXX200IVN1 2″ VEE JAW 2″

50,8 mm2.50″

63,5 mm1.34″

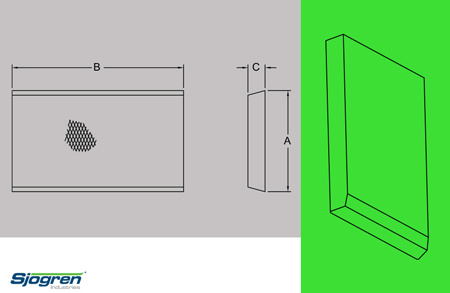

34,04 mmView Insert Holders for 3/4", 1" and 2" Models

* The Inserts’ specs are in tables further down

*Sample RequiredBase

NumberDescription A B C **BSXXX075IHN1 3/4″ INSERT

HOLDER.75″

19,05 mm2.38″

60,45 mm.95″

24,13 mm**BSXXX075IHN2 3/4″ INSERT

HOLDER.75″

19,05 mm2.75″

69,85 mm1.08″

27,43 mm**BSXXX100IHN1 1″ INSERT

HOLDER1″

25,4 mm2.50″

63,5 mm1.01″

25,65 mm**BSXXX100IHN2 1″ INSERT

HOLDER1″

25,4 mm2.50″

63,5 mm1.51″

38.35 mm**BSXXX200IHN1 2″ INSERT

HOLDER2″

50,8 mm2.50″

63,5 mm1.50″

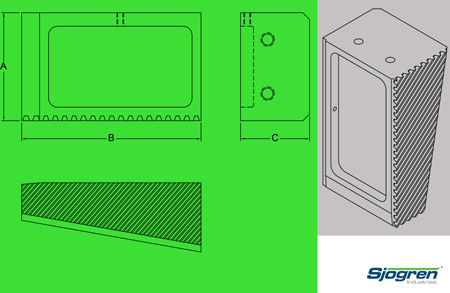

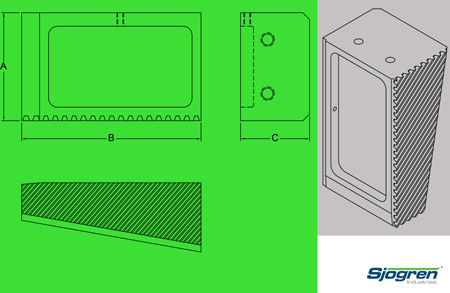

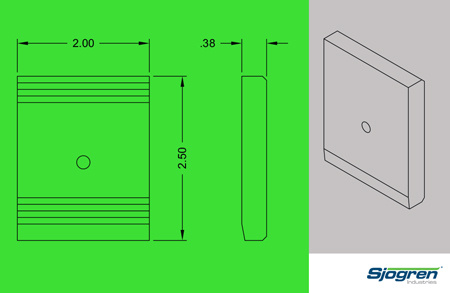

38,1 mmView Flat Jaws For 2 3/4" with Full Rack

Base

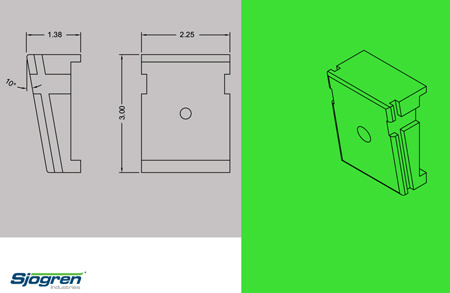

NumberDescription BSXXX225IFF1 2-1/4 FLAT JAWS View VEE Jaws for 2 1/4" Models with Full Rack

Base

NumberDescription Wire

RangeBSXXX075IVN1 2-1/4 VEE JAWS .50 – .75″

12,7 mm – 19,05 mmBSXXX225IVF2 2-1/4 VEE JAWS .75″ – 1.1″

19,05 mm – 27,94 mmView Insert Holder For 2 1/4" with Full Rack

*Corresponding insert found in table further downBase

NumberDescription BSXXX225IHF1 INSERT HOLDER View Insert Holder For 2 1/4" without Rack

*Corresponding insert found in table further downBase

NumberDescription BSXXX225IHN1 HOLDER, FLAT JAWS 2-1/4″

Jaws / Inserts / Holders Section 2

Options with lbs. Force

Satec/Baldwin Jaws, Inserts, Holders

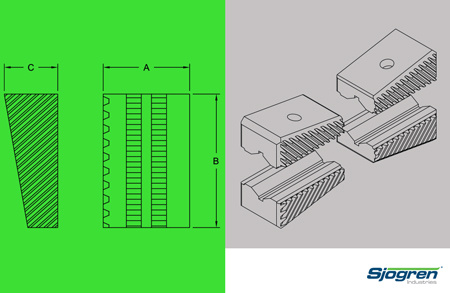

View Insert Holder with Full rack for 20,000 lbs. - 600,000 lbs. Models

*See table further down for insertsBase

NumberLoad lbs. A B C BSX20162IHF1 20-35 / 20,000 1.62″ 2.50″ 1.00″ BSX60238IHF1 60-35 / 60,000 2.38 3.75″ 1.25″ BSX60275IHF1 60,000 2.75″ 4.38″ 1.50″ BS120300IHF1 120,000 3.00″ 5.00″ 2.06″ BS200350IHF1 200,000 3.50″ 6.00″ 2.62″ BS300400IHF1 300,000 4.00″ 6.75″ 2.88″ BS400450IHF1 400,000 4.50″ 7.75″ 3.50″ BS600700IHF1 600,000 7.00″ 10″ 3.75″ View Insert Holder For 2 3/4" - 4 1/2" with Full rack for 60,000 lbs. - 400,000 lbs. Models

Base

NumberModel / lbs. Description A B C BSX60275IHF1 60,000 2-3/4″ INSERT HOLDER 2.75″ 4.38″ 1.75″ BS120300IHF1 120,000 3″ INSERT HOLDER 3.00″ 5.00″ 2.06″ BS200350IHF1 200,000 3-1/2″ INSERT HOLDER 3.50″ 6.00″ 2.62″ BS300400IHF1 300,000 4″ INSERT HOLDER 4.00″ 6.75″ 2.88″ BS400450IHF1 400,000 4 -1/2″ INSERT HOLDER 4.50″ 7.75″ 3.38″ View VEE Jaws for 1 5/8”-4 ½” Full rack for 20,000lbs. - 400,000lbs. Models

Base

NumberModel / lbs. Description A B C BSX20162IVF1 20-35 / 20,000 1-5/8″ VEE JAW 1.62″ 2.50″ 1.00″ BSX60238IVF1 60-35 / 60,000 2-3/8″ VEE JAW 2.38 3.75″ 1.25″ BSX60275IVF1 60,000 2-3/4″ VEE JAW 2.75″ 4.38″ 1.50″ BS120300IVF1 120,000 3″ VEE JAW 3.00″ 5.00″ 2.06″ BS200350IVF1 200,000 3-1/2″ VEE JAW 3.50″ 6.00″ 2.62″ BS300400IVF1 300,000 4″ VEE JAW 4.00″ 6.75″ 2.88″ BS400450IVF1 400,000 4-1/2″ VEE JAW 4.50″ 7.75″ 3.50″ View FLAT Jaw for 1 5/8” - 4 1/2” Full rack for 20,000lbs. - 400,000lbs. Models

Base

NumberModel / lbs. Description A B C BSX20162IFF1 20-35 / 20,000 1-5/8″ FLAT JAW 1.62″ 2.50″ 1.00″ BSX60238IFF1 60-35 / 60,000 2-3/8″ FLAT JAW 2.38 3.75″ 1.25″ BSX60275IFF1 60,000 2-3/4″ FLAT JAW 2.75″ 4.38″ 1.50″ BS120300IFF1 120,000 3″ FLAT JAW 3.00″ 5.00″ 2.06″ BS200350IFF1 200,000 3-1/2″ FLAT JAW 3.50″ 6.00″ 2.62″ BS300400IFF1 300,000 4″ FLAT JAW 4.00″ 6.75″ 2.88″ BS400450IFF1 400,000 4-1/2″ FLAT JAW 4.50″ 7.75″ 3.50″

Flat Inserts

Satec/Baldwin Inserts For Insert Holders

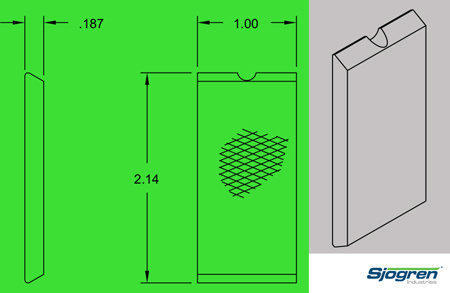

View FLAT Inserts For 1" Models

Base

NumberDescription GRXXX100IIN1 Templin Insert View Flat Inserts For 2.2", 2.5" & 3.1" for 60,000lbs. - 400,000lbs. Models

*Sample Required

*Holders listed in tables aboveBase

NumberLoad lbs. Description A B C BSX60220IIN1 60,000 2.2″ Flat

Insert2.2″ 3.75″ .38″ B120250IIN1 120,000 2.5″ Flat

Insert2.5″ 4.38″ .44″ * 200.000 * Flat

Insert* 5.38″ .50″ BS300310IIN1 300,000 3.1″ Flat

Insert3.1″ 6.12″ .62″ BS400310IIN1 400,000 3.1″ Flat

Insert3.1″ 6.12″ .62″ View FLAT Inserts For 2" Models

Base

NumberDescription BSXXX200IIN1 2″ FLAT INSERT View FLAT INSERT FOR 1 3/16" - 3" For 20,000LB. - 300,000LB. MODELS

Base

NumberModel / lbs. A B C BSX20118IIN1 20,000 1-3/16″ 2-1/16″ 1/4 BSX60187IIN1 60,000 1-7/8″ 3-3/16″ 3/8 BSX60193IIN1 60,000 1-15/16″ 3-1/2″ 11/32″ BS120225IIN1 120,000 2-1/4″ 4″ 7/16″ BS200243IIN1 200,000 2-7/16″ 4-7/8″ 7/16″ BS300300IIN1 300,000 3″ 5-3/8″ 5/8″

Talk To A Specialist

Our team of experts is here for you. Let us know about your testing application and any applicable data about your testing machine and we will provide you with your quote and associated smart part number!

See some of our satisfied customers

Tensile Testing FAQ

What are your minimum order quantities?

All of our tensile testing jaws, inserts, and holders are manufactured in sets of four. when you order a quantity of 1, you will be purchasing a set of four jaws, or four inserts, or four holders.

What are your lead times for tensile testing products?

Sjogren is proud of our nimble ability to offer the fastest lead time in the industry. You can expect an average of two – five weeks, especially for these hardened products that go through a heat-treating process.

Knowing this will allow you to order ahead of your inventory.

What do tensile testing accessories cost?

Our tensile testing lines are highly competitive and they last more than twice as long as our competitors thanks to our enhanced production equipment and expert engineering. We have set pricing on most of our tensile testing line across the board, generally within $500-$1500 per set depending on your specific customizations.

All pricing is subject to change dependent on steel and other metal market pricing.

Get Your Satec-Baldwin Jaws, Inserts, or Holders Quoted – Fast & Reliable Pricing And Delivery!

Tell us your wire processing needs, and our team will provide a tailored quote quickly. Get the best solution for consistent wire drawing today!