Features within Wire Puller Grips and products

What are wire puller grips?

Wire Puller grips are devices that are used to grip and pull wires. They are often used in applications where it is necessary to grip and pull a wire in order to move it. Puller grips are typically made of metal or plastic, and they may be either single- or double-ended.

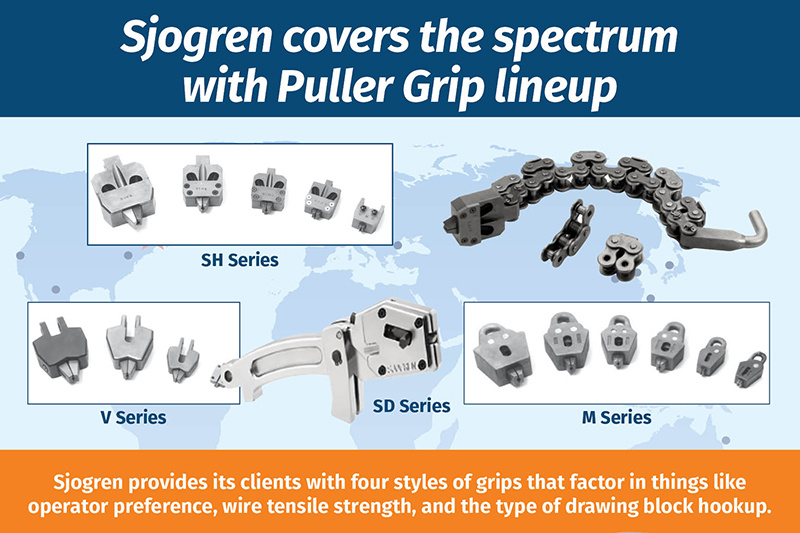

What types of puller grips does Sjogren Manufacture?

SJOGREN THUMB RELEASE PULLER

A light-duty puller of Sjogren’s own design, the thumb release puller supports greater spindle uptime by making the pulling operation more efficient — and safer — by allowing the simplified one-handed operation to open the puller jaws. Compatible with Sleeper-Hartley style puller assemblies and replacement jaws.

SJOGREN WIRE PULLER

An ergonomic and innovative design available exclusively from Sjogren, the new Sjogren Puller improves the safety of the pulling operation by enabling simplified, one-handed wire insertion. The Sjogren Puller is compatible with a wide range of puller assemblies and capstan diameters

LIGHT DUTY PULLER

For wire diameters up to .5″ / 12,7mm diameter and pull force of 10,031 lbs / 4550 kgs. These cost-effective wire-pullers are available with a wide variety of hook-up/pull chain options, including our spring-loaded safety chain which reduces block marking. Compatible with Sleeper-Hartley style puller assemblies.

MEDIUM DUTY PULLER

A puller designed for Vaughn-style blocks, Sjogren’s Medium Duty wire pullers feature one-piece casting that provides a lighter weight puller, making the operator’s job easier and more efficient. Accepts a wide range of applications: wire diameters up to 1.25″ / 31,8mm, and pull up to 50,154 lbs / 22,750 kgs.

HEAVY-DUTY PULLER

The heavy-duty construction of the puller, puller jaws, and accessories enable a greater reduction in the die-pull draw process. Components and replacement jaws are compatible with Morgan-style assemblies. The optional clevis allows for tangential die pull, which can enhance jaw life and reduce wire breakage.

HOOKS, CHAINS & ACCESSORIES

Regardless of what pulling block you have, Sjogren can provide you with pull chains and hook-ups to replace worn or broken parts. Our accessories are fully compatible with original parts; in many cases, we have designed improved safety and work efficiency properties into the components.

CHOOSE THE RIGHT PULLER

For your reference, we provide the fundamental guidelines for selecting the right puller for your application. If you have further questions, don’t hesitate to contact our engineering team — we are here to help you establish the safest, most productive wire pulling operation.

An important variable to consider is operator preference: What style puller is the operator currently using? What does the operator like/dislike about the current operation?

Additional wire/die pull data you will need includes:

- Pointed wire diameter/pointed wire diameter range

- Maximum die-pull (see below)

- Wire tensile strength

- % reduction area (see K Factor – % Reduction Table below)

- Wire toughness or hardness

- Type of drawing block hookup

- Length of puller assembly needed

The general guidelines to assist you in selecting the right puller for your operation. If you have any further questions or a specialty application, we invite you to contact our engineering team by calling 508-987-3208 or by emailing sales@sjogren.com.